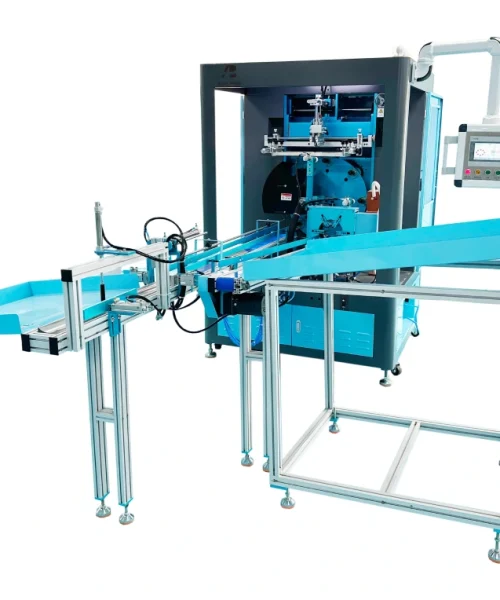

When purchasing a cryo tube printing machine, you need to understand its functions. If you need a personalized cryo tube printing machine, you can contact us in advance. The size of the product, the color, and the shape of the cryo tube can be customized individually as needed.

Next, briefly introduce the advantages of the cryo tube printing machine.

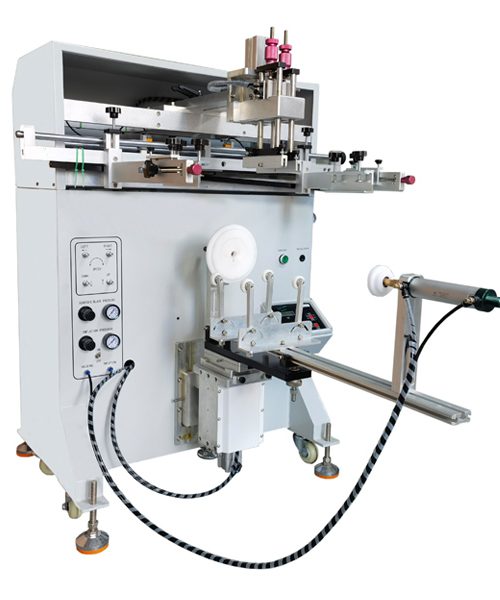

The cryo tube printer is easy to operate, and it is easy to protect the body during use. The printing process is controlled by a computer, without manual control. It can be printed to meet various shapes, such as planes, arcs, and circles, and there is no restriction on printing cryo tubes.

The input cost of the cryo tube printing machine is low, and high-speed printing is entirely suitable for mass production. It can help businesses obtain higher profits. The computer can control the automatic production process in terms of quantity, and time. The whole process is very convenient and fast. Compared with the thermal transfer process, the ultra-low printing cost of the cryo tube printing machine can save more than 70%.

-

Not affected by the material of the object:

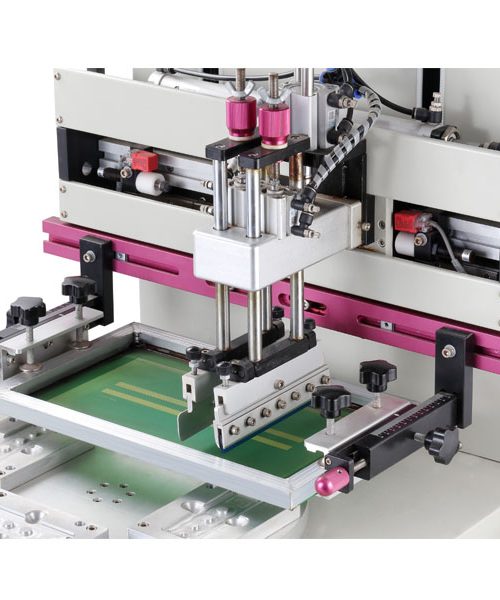

Cryo tube printing machines can print images on the surface of any material. Because the cryo tube printer does not touch the surface of the object during the printing process. So it will not be deformed by heat and pressure. And can also print it on materials that are easily bent and soft (such as leather and textiles). This is what makes the cryo tube printing machine unique.

-

High-precision perfect printing:

The cryo tube printing machine uses the special ink produced by ONCE TECH to make the output image lifelike and reach the photo quality. The idea is water-resistant, sun-proof, wear-resistant, and never fades. The cryo tube printing machine also adopts a continuous ink supply system. It is convenient for workers to add ink and reduces printing costs.