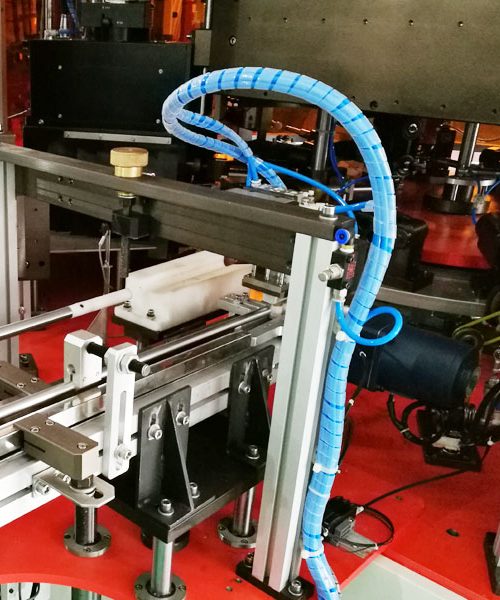

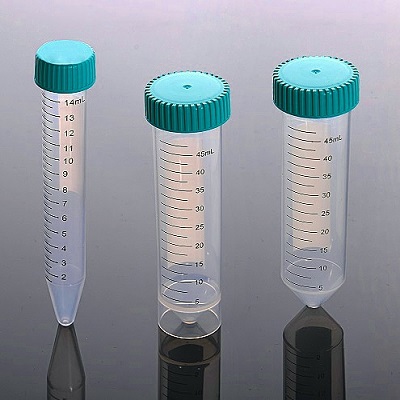

Automatic Centrifuge Tube Printing Machine

Automatic centrifuge tube printing machine prints scale on objects. Such as all kinds of centrifuge tubes, medical tubes, injectors, and other medical round containers. It is widely accessible and used in the medical field. For example, medical tubes. Centrifuge tube printing is a mass production process that does not need to design a special mold for making scale. This type of printing machine can print medical tubes no matter what kind of material they used. Generally speaking, glass medical tubes, centrifuge tubes, and plastic centrifuge tubes are the main printed objects.