Flat screen printing machine also called flatbed / flat bed screen printing machine, it is a traditional screen printing process print on the flat surface substrate.

Applications:

As for flat screen printing, so this kind of screen printer has a wide range of applications.

First the flat screen printing is widely used in industrial printing, which includes:

- Transfer paper and decal printing, like heat transfer film, water transfer film, ceramic decal printing, paper sheet, plastic sheet, metal sheet printing, etc.

- Membrane switch printing, like flexible or rigid membrane switch, appliance control switch printing, etc.

- Automotive dashboard printing, like speedometer, dashboard, etc.

- Name plate and card printing, like plastic or metal name plate, machine name plate, name plate sticker, signage, credit card, door card, etc.

- Stationery, souvenir and toy printing, like ruler, teaching tools, gift, toy parts, etc.

- Recycle bag printing, like jute bag, hand bag, etc.

- Casting cubic object printing, like basket, case, container, etc.

- Other industrial parts printing, like molded plastic panel, injection plastic part, appliance shell, etc.

Another well known application is graphic printing; it can print directly to flexible or rigid packaging paper sheet, plastic sheet, etc.

One of the important printing is glass screen printing, like solar energy glass, automotive glass, window glass, tableware glass and appliance glass, etc.

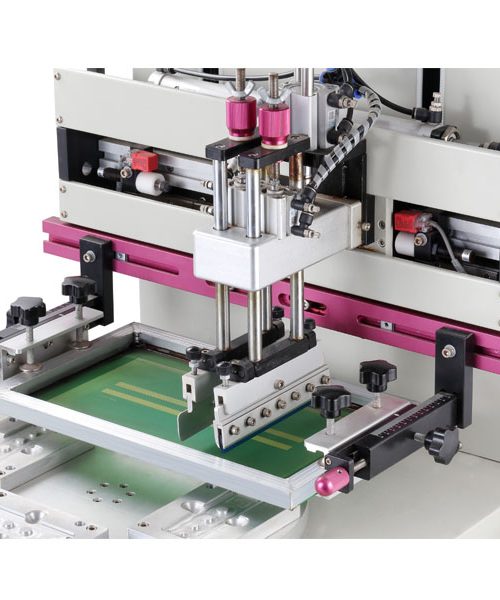

PCB (printed circuit board) printing also is a large application area for this flat screen printing, like legend printing, solder mask printing and flexible printed circuit printing, etc.

There also have optoelectronic screen printing, like phone cover lens printing, display panel printing, automotive display, etc.

Flat screen printing also used in medical part printing, like medical testing tool cover, and other medical tool parts printing.

Machine category introduction:

Now after these years development, Once Tech has this type machine range from semi automatic to fully automatic. Print size cover from small to large format size printing.

Semi automatic machine now we have pneumatic driven and electric driven type. Pneumatic driven machine usually for small size printing like 200x300mm, 200x400mm, 300x400mm, 300x500mm, this type machine using well known brand cylinder for left/right stroke, slide guide for up/down stroke to keep a stable and fast printing. Electric driven machine now we have regular print size like 300x400mm, 300x500mm, 400x600mm, 500x700mm, 600x900mm, this kind of machine with dual axis (up/down, left/right stroke) driven by AC motor with programmable PLC and touch screen controlled all the movements. This electric flat screen printing has a high precision printing tolerance, stable and continuously working condition.

We also have other semi automatic models like rotary index worktable, front/back slide worktable. This kind of machine will most suits for small size flat part fast printing, can be easy loading and unloading, and increase the printing capacity.

Fully automatic machines will be usually custom made or design for a certain project. Automatic machine can be one color to multi colors, this type of machine usually will have full screen printing process like auto loading, ionizing dust cleaning, flame treatment, screen printing, UV curing and auto unloading. Multi color printing can be came out a complete printing part at once, and with high printing speed with accurate color registration, this type of machine will much increase the production capacity and save labor cost than semi automatic machines.

Flat screen printing process:

Flat screen printing will same like cylindrical screen printing, base on different materials, screen printing have a process from pre-print, screen print to post print. Here will come to auxiliary machines. If print on plastic like PP, HDPE, PE, etc, there will need flame treatment unit (or plasma) for pre-print treatment, if print UV ink, will need UV curing machine for post print drying solution. Other parts printing usually may need drying tunnel, drying conveyor, drying rack, etc. on post printing solution.

Consumables:

For the flat bed screen printing consumables, it will be same as other screen printing methods. Squeegee, usually is the square type, hardness range from 65-85 degrees base on different materials and parts. Ink, there usually will be solvent base ink and UV base ink, but some special printing will not ink like paste, glue, butter, etc. Etched screen frame will usually is aluminum frame with screen mesh. Once could have a full service for all consumables and spare parts.

Features:

Once flat screen printer has well built machine base, high finished workmanship, like worktable micro adjustment, machining part surface treatment, make our machine in stable working and accurate printing.

Our machine have wide range of models from pneumatic to electric and automatic, so the price also have a wide range of choosing. Different printing project we can have different printing solution to meet the requirements.

Warranty & Service

Regarding the warranty, our machine will have 18 months warranty time, if any normal using damage of electric and pneumatic parts, we can send free replacement parts. And we also have a fast response with 7×14 hours on line service. Automatic machine we can send technician overseas to support if necessary.

Once tech has a strong engineer team, despite above standard screen printing machines, we also can do different project of custom made machines. We have solved many special projects, such as auto flat screen printing working line, large size (1650x850mm) PVC mat printing, coco chocolate film butter printing, etc.

Over more than 10 years exporting experience, Once Tech has a mature sale net work, including distributors, end using customers, resellers. So Once Tech flat screen printing machine is your right choice.

Flat Screen Printing Machine

Flat Screen Printing Machine

Flat Screen Printing Machine

Flat Screen Printing Machine