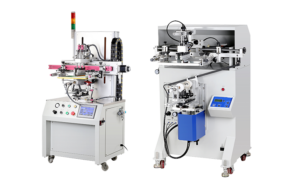

Automatic Cylindrical Screen Printing Machine Manufacturer

Automatic cylindrical screen printing machines are also known as cylindrical screen printers, cylindrical bottle printer machines, and cylindrical silk screen machines. Our automatic cylindrical printing machines are well-designed for round, oval, and other special shape containers. They can be printed on curved surfaces like plastic, glass, metal bottles, and other cylindrical containers. Cylindrical screen printing equipment is widely used in various industries. Such as daily food, personalized water bottle, cosmetic bottle manufacturing, and other industries.

At Auto Print Tech, you can buy existing cylindrical bottle printing machines or build your own equipment. Our commitment is to supply the highest quality machines at competitive and affordable prices.