Screen Printing Knowledge

What is UV Printing

UV printing is a technique that utilizes unique ultraviolet curing ink to print on an extensive range of materials. A UV printer places special ink on the material. And a UV light follows to dry and harden the ink instantly. The drying and hardening process is called curing.

Initially, the UV-ink curing process was a manicure application technique. It is used to rapidly dry nail gel polish in beauty parlors. Industrialists quickly realized that quick-drying technology could work better in industrial applications like the branding industry.

In Technical Terms

The UV ink contains small polymers and monomers, tiny molecules that combine to create polymers. The polymerization process takes place so fast that the wet ink dots do not have the time to spread and expand. As a result, you get higher-resolution prints than in conventional printing.

If you need more reasons to choose UV printing than the high-resolution outcome, UV-printed materials do not fade or wear out. The process is also environment-friendly as it gives out fewer Volatile Organic Compounds.

Conventional Printing vs. UV Printing

Most conventional printing techniques use inks with unique solvents that evaporate into the air during printing. The evaporation facilitates ink absorption onto the printing material. Then dries up, leaving a printed image on the receiving material. The printed material may require special spray powder for a quicker drying process. Additionally, these techniques do not work well with specific materials such as plastics and acrylics.

On the other hand, UV printing uses a unique ultraviolet light design. As the printing process continues, the ink is dry. The printer sprays ink on the material, and the UV light follows behind, drying the ink instantly. Ultraviolet printing can print directly on a wide range of materials. Since there is little or no solvent evaporation. This makes it easy to customize virtually a limitless range of products.

Types of UV Printer

There are three types of UV printers, as expounded below.

Flatbed Printer

As the name suggests, a flatbed UV printer has a flat surface where you place the printing material. It is best for printing flat materials such as papers, cards, and plaques. A flatbed UV printer can also print on flexible materials such as fabrics and canvas.

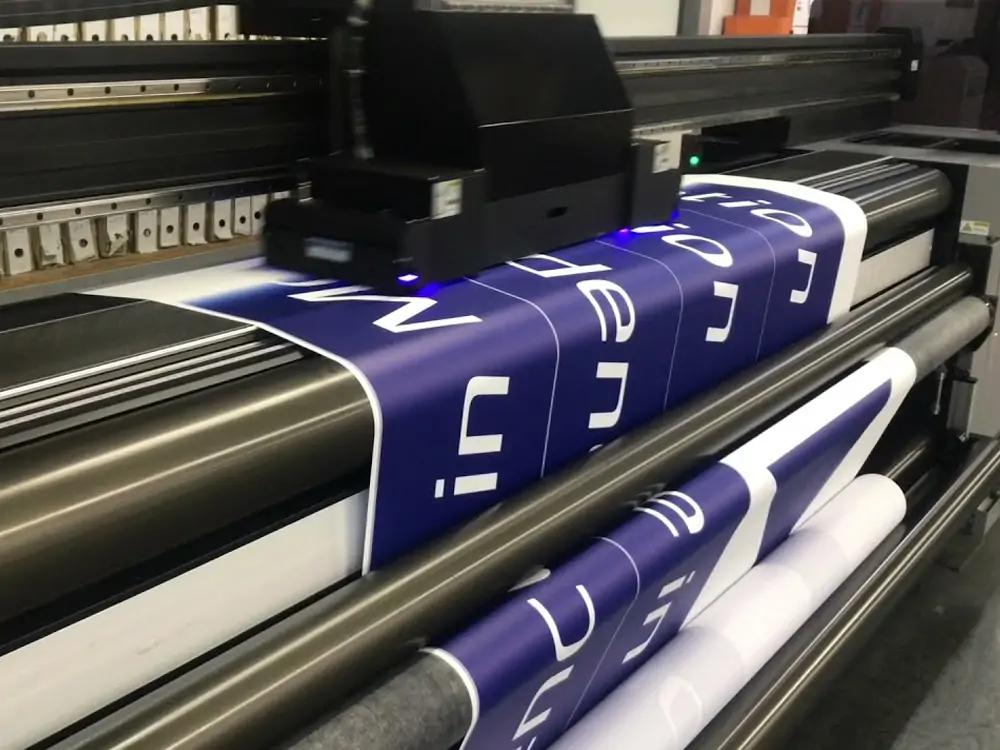

Roll-to-roll Printer

Roll-to-roll UV printers use wide rollers to avoid the formation of smudges and footprints during the printing process. The machines feature advanced technology and ergonomic structure. They are best suited for flexible materials such as fabrics and canvas.

Rotary Printer

As mentioned earlier, with UV printing, you can brand virtually anything. Rotary UV printers are uniquely engineered to print on cylindrical objects. You can use the Rotary UV printer to print on bottles and household glassware.

Components of UV Printer

If you intend to buy a UV printing machine, it is essential to master the core parts of the printer. Operating and maintaining a machine you know and understand better is relatively easy. These are the main parts of a UV printer.

Print Head

A UV print head is responsible for the quality of the final print. The head comprises tiny nozzles that drop ink systematically to create the image. The quality of the print head and its nozzles determine the accuracy, speed, and stability of your UV printing machine.

Motor

UV printers have belts that carry the print head from one end of the machine to the other. The machine has a motor that powers this belt and facilitates printing. Most UV printing machines use a premium servo motor and a rack-and-pinion system to move the print head precisely during printing.

Sensors

UV printers have various sensors for different functions. The sensors include a carriage sensor, height sensor, and ink cartridge sensor, among others. The sensors are to ensure the machine functions properly all the time.

Curing System

The UV curing system is what makes a UV printer unique. It helps dry and harden the ink instantly as the printing process continues.

Benefits of UV Printing

It is without a doubt that ultraviolet printing technology is taking the sign and print industry by storm. UV printing is ecological and offers sign manufacturing companies multiple benefits as follows.

Wider Scope of Applications

The modern sign and print industry is quite competitive. As a result, branding companies ought to adapt to the market demands by being able to offer multiple services under the same roof. UV printing is the perfect tool to remain ahead of the competition. Because it allows you to print on almost every material using the same machine. Since ink curing occurs instantly without generating heat, UV printing can easily print on heat-sensitive materials. You can also print on electronic devices, which are otherwise vulnerable when exposed to heat.

Faster Printing Process

Fast delivery is among the most significant determinants of a client’s supplier. Because of this, many sign and print professionals are adopting UV printing technology.

Because the ink curing happens instantly, UV-printed products are always ready for delivery when you remove them from the printer. For customization and printing of promotional items, UV printing is way faster than other techniques, such as screen printing. There is no setup time or waiting for the ink to dry.

If you run a signage company, UV printing on boards and other sign-making materials is a one-time process. Typically, you would print a vinyl sticker. Paste it on a board, and finish by applying a laminating film on top of the artwork.

Durable Prints/ Excellent Finish

UV printing creates durable imprints that do not fade because of sunlight. Unlike vinyl stickers and other sign-manufacturing processes, you do not need to laminate UV-printed materials to preserve the quality of the image. UV printing leaves an excellent finish. Because the instant ink-curing prevents ink drops from spreading and expanding. UV printers are the best machines for printing high-quality photos.

Wide Range of Print Effects

Another fantastic benefit of UV printing technology is the possibility of creating different print effects. With a UV printer, you can print the UV spot effect using gloss ink. Some print effects with glossy highlights and raised or embossed textures can be achieved with this special ink. You can even create brail text much easier and faster than other methods using a UV printer.

How Can You Make Money With A UV Printer

What can you do with a UV-printing machine? Better still, what can’t you do?

There is nearly nothing you cannot print with a UV printer. The quick ink-curing process allows you to print on virtually every material and every surface.

You can increase the printing possibilities by including cylindrical objects in the mix. Although this option may not work with every UV printer, adding cylindrical objects in the attachment significantly expands your operation scope. It allows you to print on products such as glassware, and wine bottles, among other products.

So, are you still wondering how to make money with a UV printer?

Adding UV printing to your sign and print business expands your business reach exponentially. You can print on materials that are up to 100mm thick.

UV printing is so versatile. It allows you to print on curved objects such as computer mice, golf balls, ball pens, and power banks, among other objects. You can also utilize UV printing technology to create trophies for your local sports teams, schools, and community organizations.

You can partner with these organizations to ensure they only buy from you, providing a regular customer flow.

Profit margins on many UV-printed materials range from 100 percent to even 1,000 percent. The amount you charge per order depends on the output quality and complexity of the project.

UV printing is highly efficient and cost-effective since there is little or no ink wastage. It is also quite difficult to damage an object while printing on a UV printer. With this information, you can see that UV printing is a lucrative investment. You can hardly make any losses when working with a UV printer. Only profits.

Conclusion

UV printing technology is a trend. And it will continue like that until it plants its roots deep in the sign and print industry. For a long time, these machines have been out of reach for individuals and small business entities. Primarily because they were costly to purchase. Today, you can find a quality UV printer at a relatively cheaper price.

Still, they are not as affordable as their conventional counterparts. A flatbed UV printer sells for between $25,000 and $85,000. The wide-format UV flatbeds cost between $78,000 and $115,000. While these numbers are relatively high, they do not lock out small business enterprises with limited access to funds. You can choose the more affordable small UV machines, such as the desktop UV printers, that cost from $2,000 to around $6,000. They provide a perfect starting place as you grow financial muscle for heavy-duty UV printing machines.