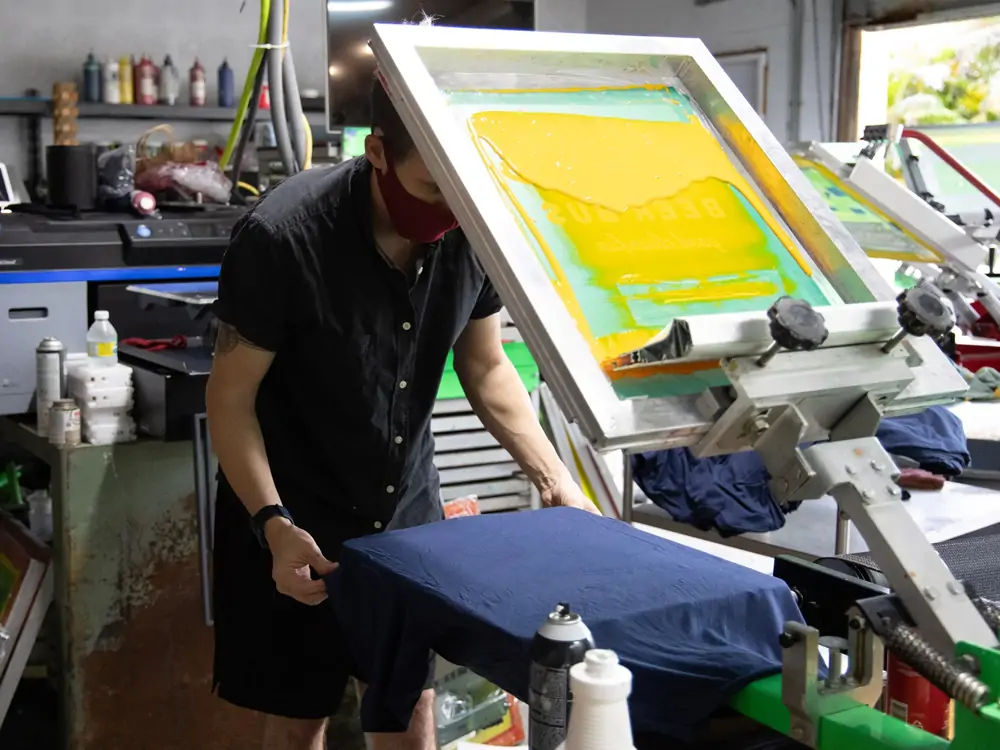

Screen printing is a popular printing method. The process is simple. It involves transferring a design to a fabric or other material using a screen, also known as a “mesh” or “stencil”. It is a versatile method used to print on various materials. Including paper, fabric, plastic, and even metal.

Screen printing is popular for custom t-shirts, posters, and other promotional items. Because it has durability and vibrant color features. The process is relatively simple and cost-effective. It can be used to create professional-looking prints on various materials.

In this article, we will discuss the basics of screen printing and how to screen print on different materials. And you can learn the advantages and disadvantages of each material and the steps you need to take to create a print successfully.

What is Screen Printing?

Screen printing involves transferring a design onto a fabric or other material using a screen, also known as a “mesh” or “stencil”. The design is transferred to the screen using a stencil, created using a photo emulsion and light exposure. Then the screen is placed on top of the fabric or other material, and ink is forced through the screen, creating a print. Screen printing is a popular selection for custom t-shirts, posters, and other promotional items because of its durability and vibrant colors. It is also a versatile printing method that can print on various materials, including paper, fabric, plastic, wood, and metal.

Items Used in Screen printing

You’ll need a few key pieces of equipment to create custom prints. These are the essential tools used for screen printing. You can create custom prints for various projects with suitable materials and equipment.

- Screen: The screen is the foundation for your design. It is a piece of mesh fabric stretched over a frame. It is the tool used to transfer the ink onto the substrate.

- Ink: The ink is the medium used to color your prints. Depending on the substrate used, it is available in various colors and formulations.

- Squeegee: The squeegee spreads the ink over the substrate. A flat rubber blade is pulled over the screen to force the ink into the substrate.

- Substrate: The substrate is the material you print the design on. Common substrates include paper, fabric, wood, metal, and plastic.

- Exposure Unit: An exposure unit exposes the screen to light. This light is used to harden the design onto the screen.

- Press: A press is used to press the design onto the substrate. It is a device that applies pressure to the screen to force the ink into the substrate.

How to Screen Print on Different Materials

Screen printing can be used on various materials, but the process may differ slightly depending on your printing material. Here are some tips on how to screen print on different materials:

- Paper: Paper is one of the most common materials used in screen printing. The process is relatively simple, transferring a design onto paper using a screen and ink. You will need to use a mesh screen and water-based ink to print on paper. You will also need a backing board to keep the paper from moving while it is printed.

- Fabric: Fabric is another popular material for screen printing. The process is slightly different from paper, as it requires using a heavier mesh screen and ink explicitly designed for use on fabric. You must also pretreat the fabric to ensure the ink adheres appropriately. To pretreat fabric, soak it in water and a mild detergent.

- Plastic: Plastic is an excellent material for screen printing, as it is durable and can be printed in various colors. The process is similar to printing on fabric, as you will need to use a heavier mesh screen and ink explicitly designed for use on plastic. You must also pretreat the plastic to ensure the ink adheres appropriately.

- Wood: Wood is an excellent material for screen printing, as it is durable and can be printed in various colors. The process is similar to printing on fabric and plastic, but you will need to use a heavier mesh screen and ink explicitly designed for use on wood. However, you must pretreat the wood to ensure the ink adheres appropriately.

- Metal: Metal is an excellent material for screen printing, as it is durable and can be printed in various colors. The process is similar to fabric, plastic, and wood, but you will need to use a heavier mesh screen and ink designed specifically for use on metal. In addition, you will pretreat the metal to ensure that the ink adheres appropriately.

How to Screen Print a with Screen Printing Machine

- Prepare Your Screen: Start by placing your screen over the screen printing machine. Ensure the screen is firmly secured and the printing area is free from dust or debris.

- Prepare Your Ink: Load your screen printing ink into the screen printer and make sure the ink is evenly distributed.

- Prepare Your Design: Place your design onto the screen printing machine and ensure it is centered on the screen.

- Start the Print: Turn on the screen printing machine and adjust the settings according to your desired result.

- Print: Press the start button to begin printing, and watch as your design is transferred to the material.

- Finishing: Once the printing process is complete, remove the material from the machine and inspect the quality of your print. Touch up any areas that need more attention with a brush or sponge.

- Clean Up: After completing your print, you must clean up the screen printing machine. Remove any excess ink, clean the screen with water, and ensure all surfaces are dry before putting them away.

Silk Screen Printing Process

Silk is a delicate material and requires special care when printing on it. To begin, decide the design you want to print. Once you have your plan, transfer it to a silk screen. The silk screen is the frame that holds the structure in place and is used to transfer the ink to the fabric.

The silkscreen must be treated with a special emulsion before it is ready. Next, you will need to prepare the fabric for silk screen printing. Before printing, the material should be washed and ironed. This will help remove any dust or dirt particles on the fabric, which can cause imperfections when printing. Make sure that the fabric is completely dry before beginning. Once the material is ready, then you can start printing. Place the fabric on a flat surface and place the silk screen over the fabric. Place a layer of ink on the screen and use a squeegee to spread it over the material.

Types of Screen Printing Methods

There are several different types of screen printing methods available. Some can be through the screen printer machine, while others through traditional printing.

- Flatbed Printing: This is the most common type of screen printing method. It involves a screen or mesh that is mounted onto a flat surface. Ink is then applied to the screen, and a squeegee is used to push the ink through the mesh onto the substrate. Flatbed printing is ideal for large production runs and is commonly used for printing on fabrics, paper, and other substrates.

- Rotary Screen Printing: This method involves a cylindrical screen, or meshes mounted onto a rotating drum. Ink is then applied to the screen and rotated in a circular motion, pushing the ink through the mesh onto the substrate. Rotary screen printing is ideal for cylindrical items like bottles and cans.

- Digital Printing: This method involves printing a digital image onto the substrate using a specialized screen printer. Digital printing is ideal for short-run jobs as it is fast, accurate, and cost-effective.

Advantages and Disadvantages of Screen Printing

Screen printing has several advantages and disadvantages.

Advantages of Screen Printing

- Durability: Screen printing is a durable method that can withstand wear and tear.

- Vibrant Colors: Screen printing can produce vibrant, eye-catching colors that will last a long time.

- Flexibility: Screen printing can be used to print on various materials.

Disadvantages of Screen Printing

- Cost: Screen printing can be more expensive than other printing methods.

- Time: Screen printing can be a time-consuming process.

- Skill: Screen printing requires skill and experience to ensure the best results.

Conclusion

Screen printing is a popular printing method that can be used to create professional-looking prints on various materials. It is a cost-effective, versatile method that produces vibrant colors lasting long. The process can differ slightly depending on the material you print on, but the basics are the same. All the necessary materials for screen printing should be readily available before printing. Also, a screen printer machine helps complete your design within a limited time. Screen printing has several advantages and disadvantages; weighing them before deciding which is the right choice for your project is essential.