As a professional screen printing machine manufacturer, Once is committed to providing customers with excellent and the best screen printing machines. ONCE has a highly skilled and experienced technological research and development team. At the same time, it can design products that satisfy customers according to their requirements. With years of experience in screen printer machine production, ONCE has won praises for its exceptional quality and has quickly dominated the market.

Now you will learn the top 10 screen print machines that are popular in user experience. You have reached the right place if you’re looking for the best machine. We can help you select the best screen printing machine to suit your needs. Let’s have a look at the 10 best screen printing machines.

What’s the Best Screen Printing Machine

For most people, buying a screen print machine means spending years of savings. So this is a long-term investment. It is very necessary to choose the best screen printing machine. If you are on a budget, then a single-color silk screen printing machine will suffice. If you have enough budget, then an expensive screen printer machine will definitely bring you an unparalleled experience. Its performance is incomparable to cheaper machines. Of course, what suits you is the best.

Top 1 One Color Automatic UV Silk Screen Bottle Printing Machine

ONCE, a bottle printing machine manufacturer offers a print testing service for client bottles samples so that you can verify the quality of the print before placing your order.

OS-767-1C is a fully automatic UV curing single-color screen printing bottle machine, also commonly known as a single-color bottle UV screenprinting machine. It can be used to print round, oval, and square bottles. Such as metal bottles, plastic bottles, and glass bottles. One of the biggest advantages of this 1 color automatic screen printing machine is the fast printing speed, which can print 4200 bottles per hour.

Specifications of This Bottle Screen Printing Machine

| Model NO.: | OS-767-1C |

| Round container size: | Diameter: φ10-100mm, Height: 30-260mm |

| Round container max. print area: | L 260 x W220mm |

| Oval container size: | R: 10-250mm, Height: 30-260mm |

| Oval container max. print area: | L 120 x W220mm |

| Drive: | Mechanical Driven |

| Control system: | OMRON PLC & Touch Screen |

| Max. printing capacity: | 70 pcs/min |

| Registration tolerance: | +/- 0.2 mm |

| Infeed conveyor: | 1 unit, length: 2 meters |

| Deionizing device: | 1 unit |

| Flame treating system: | 1 unit, LP gas |

| Motor: | ITALY MOTOVARIO |

| Print head: | 1 unit |

| UV system: | 1 unit intelligent UV system, 5KW per each |

| Outfeed conveyor: | 1 unit, Length: 2 meters |

| Frequency Converter: | OMRON |

| Pneumatic parts: | FESTO or SMC |

| Electrical: | 380V 3phase 50Hz |

| Air requirement: | 5-7 bar |

| Air consumption: | 85 liter/ minute max. (per color) |

| Power consumption: | 5.4 KW/color x 1 |

| Machine size(LxWxH): | Main machine: 2300x1800x1700mm |

| Weight: | 1600 KG |

Four Reasons Why This Screen Print Machine Sells Well:

- High Speed

The printing speed is up to 4200 bottles per hour, 22 pieces per minute.

- Print Diversity

Can be printed on the square, round and oval bottles.

- High Stability

Mechanically driven bottle conveying with high stability.

- Low Consumption

A smart UV system reduces energy consumption.

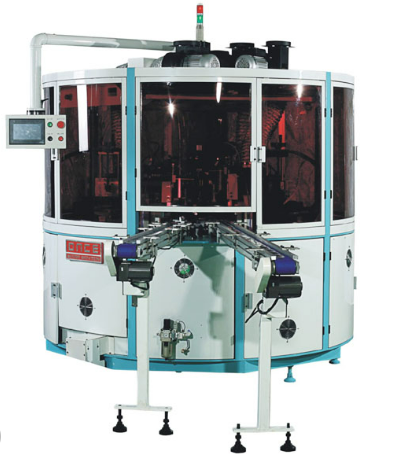

Top 2 One Color Automatic Cosmetic Tube Screen Printing Machine

OS-175 can provide you with an unparalleled power experience. It is a 1 color automatic UV screenprinting machine. Suitable for screen printing on flexible or rigid plastic tubes, plastic cans. As long as your container is a cylinder up to 75mm in diameter. The configuration of the OS-175 is quite complete. Including the main drive motor produced in Europe, the intelligent UV curing device, and the feeding belt.

Specifications of This Tube Screen Printing Machine

| Model NO.: | OS-175 |

| Print product size (DiameterxLength): | Ø10mm-Ø75mm, L: 20mm-230mm |

| Max. print area: | 236x170mm |

| Max. printing speed: | 60-80 pcs/min |

| Registration tolerance: | +/- 0.2 |

| Drive: | Mechanical driven |

| Control system: | OMRON PLC & Touch Screen |

| Stations: | 12 stations |

| Deionizing device: | 1 unit |

| Flame treating system: | 1 unit |

| Print head: | 1 unit |

| UV system: | 1 unit intelligent UV system |

| UV lamp power: | 3.6 KW |

| Main Motor: | ITALY MOTOVARIO |

| Pneumatic parts: | Japan SMC |

| Photoelectric Sensor: | Japan Keyence |

| Frequency Converter: | Japan OMRON |

| Indexer | Japan SANKYO |

| Electrical Supply: | 380V/480V 3phase 50Hz/60Hz |

| Air requirement: | 6-8 bar |

| Power consumption: | 4.5 KW |

| Machine Dimension (LxWxH): | 1500x1180x1900mm |

| Weight: | 1500 KG |

Six Reasons Why This Screen Printer Machine Sells Well:

- High-speed vertical rotary UV screen printing machine.

- Print speed up to 80ppm.

- The blade angle and height can be adjusted.

- Setup and transitions are quick and easy.

- Equip with flame treatment and deionizing device.

- Has a mechanically synchronized print head for precise printing.

Top 3 Multicolor Semi-Automatic Round Bottle Screen Printing Machine

This economical standard round bottle press is one of the most popular. OS-400S is capable of multi-color printing. It can print up to 110mm in diameter and easily convert different size bottles on the programmable touch screen. The maximum printing area can reach L350xH220mm. It can print a variety of round containers, such as plastic and metal bottles. Also, it has servo-driven printing and motor-driven up and down strokes. A programmable PLC touch screen controls all actions, not only fast but also stable printing.

Specifications of This Bottle Screen Printing Machine

| Model NO.: | OS-400S |

| Print shape | Round |

| Up & Downstroke Driven: | Electric motor |

| Print stroke Driven: | Servo motor |

| Re-registration system: | Servo motor & Optical sensor |

| Control system: | Brand PLC & Touch Screen |

| Print round diameter: | Ø7mm(0.276″)-Ø110mm (4.33″) |

| Maximun print area: | L350mm x H220 mm |

| Maximum screen frame size: | 800 x 400mm (31.50″ x 15.74″) |

| Printing cycle speed: | 2000 cycles/hour |

| Registration tolerance: | +/- 0.3-0.5 mm (except products tolerance) |

| Electrical supply: | 110V/220V 50-60Hz 2.5KW |

| Air requirement: | 5-7 bar |

| Machine dimension: | L900 x W800 x H1450 mm |

| Weight: | 200 kg (440.92 lbs) |

Five Reasons Why This Screenprinting Machine Sells Well:

- Simple tool changes can be implemented quickly.

- Optical sensor from Germany with high reading accuracy.

- Multi-color printing is possible, suitable for different kinds of containers.

- Programmable PLC and touch screen.

- Scraper inclination angle and height are adjustable.

Top 4 Semi-Automatic Round Bottle Screen Printing Machine

OS-400 is a well-designed multifunctional semi-automatic cylinder screen printing machine. The maximum printing diameter of this machine is 110mm. It is a printing machine specially used for round and oval objects such as bottles and cups. Easy-to-operate PCB board controls, precise mechanical registration, and a pneumatic drive system make this circular screen printer the perfect all-purpose screen-printer. Print speeds of up to 1,200 parts per hour with a simple die changeover.

Specifications of This Bottle Screen Printing Machine

| Model Number: | OS-400 |

| Drive System: | Pneumatic |

| Frame Up/Down Stroke: | 100mm (3.94″) |

| Maximum Print Area Round: Maximum Print Area Oval: Maximum Print Area Flat: | 110mm (4.33″) Ø340mm (13.39″) Arc Length 200 x 320mm (7.87″ x 12.60″) |

| Working Table Size: | 250 x 350mm (9.84″ x 13.78″) |

| Table Adjustment: | X,Y ± 15mm / θ 15 ° |

| Maximum Screen Frame Size: | 380 x 580mm (14.96″ x 22.83″) |

| Screen Frame Thickness: | 18 – 25mm (0.71″ -0.98″) |

| Squeegee Angle: | 0-15° |

| Printing Cycle Speed: | 1,200 cycles/hr |

| Squeegee Speed: | 20/min |

| Squeegee Pressure: | 2 – 4 Bar |

| Electric Source: | 110V/220V 50-60Hz 50W |

| Air Pressure Input: | 80 psi |

| Air Consumption: | 0.7 L/cycle |

| Machine Weight: | 150 kg (330.69 lbs) |

| Machine Weight (including crating): | 230 kg (507.06 lbs) |

| Dimensions (L x W x H): | 1,000 x 950 x 1,400mm |

| Crate Dimensions: | 1,080 x 1,010 x 1,520mm |

Five Reasons Why This Screen Print Machine Sells Well:

- With shock absorbers, pneumatically controlled.

- The screen frame angle and tilt are adjustable.

- Easy-to-operate PCB board controls.

- Vertical lift with adjustable height.

- With X/Y/R positioning pendant table.

Top 5 Three Color Automatic Flat Bed Screen Printing Machine

This UV screen printing machine is fully automated and can be used on flat surfaces. It has high production efficiency. The ink is automatically cured by high-power UV lamps. UV lamps are located behind each printing station. And the OS-R324 is equipped with a SITI main drive motor as well as a US-made UV curing unit and a high-intensity mercury UV bulb. There is a pre-flame treatment station and deionization. This ensures high-quality print results and fewer errors. Once provides tools such as flat pens, printing dressing boxes, stationery rulers, etc.

Specifications of This Flat Bed Screen Printing Machine

| Model NO.: | OS-F324 |

| Print product size: | L160 x W160 x H100 mm |

| Max. print area: | L110 x W90 mm |

| Max. printing speed: | 45 pcs/min |

| Drive: | Mechanical driven |

| Flame treating system: | 1 unit |

| Print head: | 3 units |

| Stations: | 24 stations |

| UV system: | 3 units electronic UV system, 5KW per each |

| Deionizing device: | 1 unit |

| Motor: | ITALY SITI |

| Control system: | OMRON PLC & Touch Screen |

| Pneumatic parts: | Japan SMC |

| Electrical supply: | 380V/480V 3phase 50Hz/60Hz |

| Air requirement: | 6-8bar |

| Power consumption: | 10 KW |

| Machine dimension: | L4950 x W3150 x H2350 mm |

| Weight: | 1500 KG |

Six Reasons Why This Automatic Screen Printing Machine Sells Well:

- Automatic loading and unloading system.

- Quick and easy conversion system.

- The scraper angle and height are adjustable.

- Print area: 110 x 90 mm (4.33 in x 3.54 in).

- U.S.-made UV curing unit.

- Print speed up to 45ppm.

Top 6 OS Series Electric Flat Screen Printing Machine

OS series flatbed silk screen printing machines are widely used in industrial product printing, paper printing, graphic printing, glass printing, etc. There are several different models of flatbed screen printing machines in this series. Each model prints at a different size. Such as 300x500mm, 400x600mm, 600x900mm, 700x1200mm, and even larger sizes. This range of flat-screen printers is ideal for printing graphic panels, overlays, membrane switches, and transfer papers of all sizes. In addition, flat vertical lifting enables operators to easily load and unload parts and easily inspect printed parts during operation.

Specifications of This Electric Flat Bed Screen Printing Machine

| Model | OS-3050V | OS-4060V | OS-5070V | OS-6090V | OS-70120V |

| Frame up/down stroke | 150mm | 200mm | 200mm | 200mm | 200mm |

| Print stroke(left&right) | 550mm | 700mm | 800mm | 1000mm | 1300mm |

| Max print area | 300x500mm | 400x600mm | 500x700mm | 600x900mm | 700x1200mm |

| Vacuum table size | 300x500mm | 400x600mm | 500x700mm | 600x900mm | 700x1200mm |

| Working table size | 350x600mm | 500x700mm | 600x800mm | 700x1000mm | 800x1300mm |

| Max frame size | 500x830mm | 600x9300mm | 700x1130mm | 800x13000mm | 1000x14500mm |

| Screen frame thickness | 50.8mm | ||||

| Squeegee pressure | 2-4 bar | ||||

| Max print speed | 1,200 cycles/hr | 800 cycles/hr | 800 cycles/hr | 800 cycles/hr | 600 cycles/hr |

| Electric source | 110/220/230V 50/60Hz | 110/220/230V 50/60Hz | 110/220/230V 50/60Hz | 380V 50/60Hz | 380V 50/60Hz |

| Machine weight | 190kg | 320kg | 380kg | 660kg | 680kg |

| Machine dimension | 800x1050x1550mm | 1150x1000x1700mm | 1100x1300x1650mm | 1350x1350x1700mm | 1450x1650x1700mm |

Five Reasons Why This Machine Sells Well:

- Stable and durable.

- With the emergency stop button.

- Footswitch control.

- Touch screen control is programmable and easy to operate.

- The dual-axis AC motor drive can realize horizontal and vertical work.