Screen Printing Knowledge

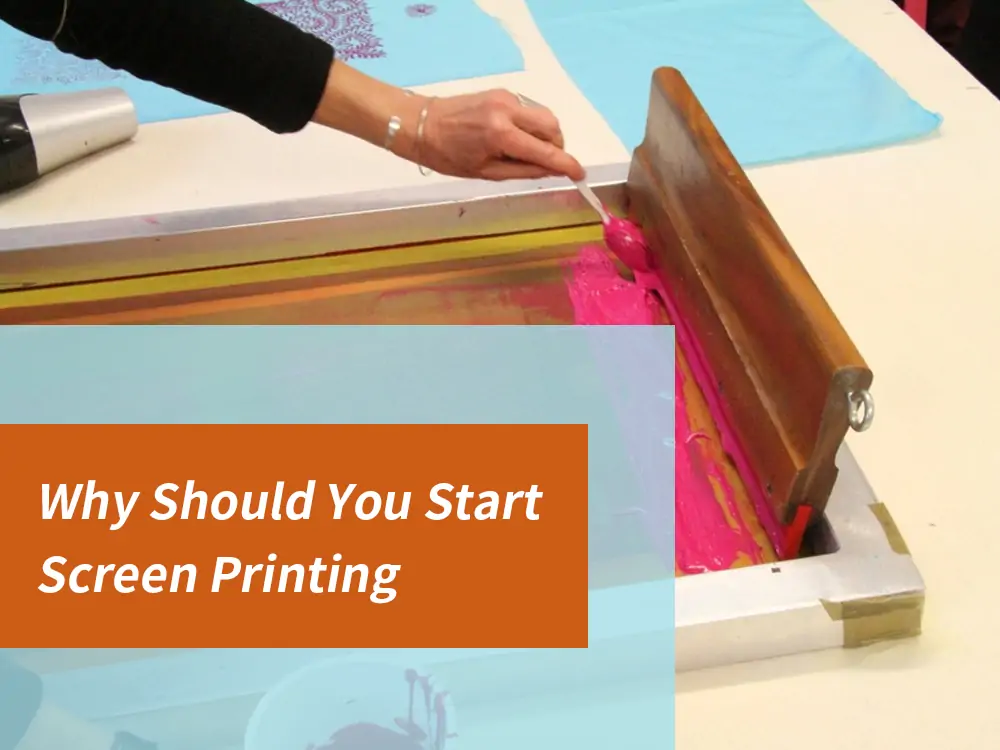

Why Should You Start Screen Printing

Screen printing is once known as silkscreen printing. It is an art where webbing transfers dye to a fat surface. Paper and fabric are the most common screen printing surfaces. Though printing on wood, glass, plastic, and metal is possible. Screen printing is mainly used for the production of realistic pictures, even in cases of unlighted fabrics. The dye or ink rests on the paper’s surfaces, giving the print a pleasantly tangible quality. This process can also be referred to as serigraphy. Screen printing is an essential technique for creating posters but is mainly used to make textiles and fabrics.

A challenging and imaginative method is screen printing. Many people who become screen printers do so as a pastime. Or as a result of using other techniques for clothing decoration, such as vinyl or embroidery. Screen printing can significantly impact your company, even with a small initial expenditure. Let’s discuss the prerequisites for screen printing and how it may be coupled with other methods of clothing embellishment.

Do You Need to Start Screen Printing

Do you enjoy a good challenge? Do you want to improve your crafting skills? Screen printing is a creative and challenging outlet. It takes time, patience, and a desire to learn by experimenting to learn how to screen print. There is no one way to do it, as there is with many creative trades. You can broaden your resume and create high-quality garments by learning to screen print.

Another compelling reason to screen print is quality control. Assume you own a clothing line. You’re sending artwork to a company that will print it for you. However, the finished product only sometimes meets your expectations. What are you going to do about it? Begin screen printing. You can maintain control over the quality of your brand’s garments and reproduce them at that level.

Forming a Side Hustle

Many newcomers to screen printing begin with just a screen and hinge clamps mounted to a table and create one-color designs. Because of this method, screen printing can be easily added to a crafting setup. Printing shirts for parties, family vacations, or groups you’re involved in is a great way to get your feet wet in screen printing. With so much free education available, learning the basics of screen printing is simple.

There are many ways to personalize your business and make it unique, regardless of how you use screen printing. Take, for example, David Baker of PRNT SCRN Screen Printing. David works full-time but prints t-shirts out of his garage on the side. Other businesses, such as Aesthetic Imprints, began in whatever space was available and gradually expanded to make screen printing their full-time job.

Methods for Pairing Garments for Decoration

One of the most enjoyable aspects of screen printing? It can be used in conjunction with other methods of garment decoration. Embroidery is the most common decoration method used in conjunction with screen printing. It adds a wide variety of garment decorations to whatever you’re doing. Do you want your logo embroidered with a 5-color back print? To make one-of-a-kind garments, combine embroidery and screen printing.

Many screen printers use heat transfers and screen printing to speed up production while adding a personal touch to the garment. Heat transfers are ideal for low-volume, long-term applications. Assume a client owns a construction company and requires five shirts. You could screen print them or use transfers whenever the customer needs more shirts. By printing heat transfers, you can have hundreds of those prints ready to heat press onto a garment as soon as the customer needs the shirts.

Heat transfers are also excellent for prints you know you’ll frequently use. Such as brand logos or neck labels. Create or order the transfers in bulk and keep them on hand when needed. A heat press is an excellent tool for any decorator in their toolbox for purposes other than transfers. Printers can use a heat press to decorate garments with foil and cure the ink. Many specialized heat presses allow you to decorate specialty items such as hats or mugs and distinguish your brand.

What Do I Require?

Screen printing typically entails screen creation, printing, and reclaiming. If you’re just getting started, there are many ways to get started in screen printing. This includes a washout booth, exposure unit, film, cleaning chemicals, a press, ink, and other items. These can be purchased separately or in a kit for a one-stop-shop option that includes everything you’ll need to succeed.

Many screen printers seek a less traditional screen printing process to suit their lifestyle, needs, and space constraints. Do you want to avoid coating and burning screens? Janet from Pigskins & Pigtails used vinyl to make screens. Janet cuts vinyl designs for the screens with her Circuit, then tapes them up and screens prints with water-based ink.

Need more space for a press with multiple color heads? Small presses like the Riley Hopkins 150 or DIY press are available. As previously stated, a screen with hinge clamps mounted to a cart or table will suffice for simple jobs. Some shops take an even more unconventional approach, making rubber stencils and stamping the shirt with inked-up stamps.

Screen Restoration

Reclaiming screens can be messy. And some printers need more space or capability to do so efficiently. While a spare bathroom can be converted into a reclaimed room, rinsing out screens in a bathtub can stain the tub and send chemicals down the drain. The good news is that it is entirely possible to outsource screen creation and reclaim. Find a print shop in your area that will recycle your screens. You can keep that spare bathroom chemical-free by paying someone else to reclaim screens.

A small washout booth with a DIY filtration system is another option for keeping reclaim in-house. Filtration is essential when reclaiming screens. Because chemicals, emulsions, and ink can clog pipes and cause later problems. You can conquer reclaim in your space by making a filtration system out of buckets and screens with different mesh sizes. There is a way where there is a will to screen print. It all comes down to your imagination and willingness to try new things to see what works best for you.

Screen printing can benefit any creative individual looking to learn something new. Regardless of their level of interest or investment. Examine all the free education options and delve into the wonderful world of screen printing. Combine several creative hobbies into one fantastic side business and earn money doing what you enjoy.

Starting a Screen Printing Business

Like any other profitable business, the screen printing business is also very profitable once using the best ways possible. The screen printing business is complex. It needs high management and cares during manufacture, production, and maintenance. Marketing is also a significant factor in screen printing.

Ways to Grow and Market the Screen Printing Business Include:

- Using social media platforms like Facebook, YouTube, and Twitter to show the public the benefits and location where the screen printing company is located.

- Keeping up with changes in the community by changing and making the product likable to the people around for more buyers.

- Making a deal with promoters and other companies to help improve the income state of the business.

- Being unique in production and quality attracts more buyers since the buyer will always go for the quality.

- Being welcoming and friendly to the customers to attract more buyers.

Advantages of Screen Printing

Robustness

Due to the composition and thickness of the ink, designs printed using screen printing can withstand greater pressure than other techniques without compromising print quality.

Ideal for Big Orders

It is best suited for large orders because this method requires making screens for each color used in an artwork. The number of garments ordered in order increases as the cost per unit decreases.

Exceptional Finish

Most printing methods cannot match the vivid colors produced by screen printing. The dots used in direct-to-garment (DTG) printing are cyan, magenta, yellow, and black (CMYK).

Ink

Compared to other printing methods, screen printing enables the application of an ink layer. Screen printing allows for a thicker ink layer than other techniques, resulting in more options for the piece’s finish.

Flexibility

It is difficult to find a printing method that is as versatile as screen printing. It can be done on almost any flat surface, including fabric, wood, plastic, and even metal, among many others.

Conclusion

It is a fundamental process that remains constant, whether automated or done by hand. The tools are easily replaceable and will not become obsolete quickly as other technologies. Screen Printing is now one of the speedy growing industries and should be promoted and improved. If you have plans to start screen printing, that is great!