Printing mugs is a fascinating process. It involves customizing ceramic mugs with designs, images, and text. And it has become a popular trend in personalized gifts and promotional items in the modern era. Printing on mugs is versatile and creative. It makes ordinary mugs unique and meaningful. Perhaps you’d like to craft distinctive designs for your loved ones. Or, you may be an entrepreneur looking to start a lucrative business. By employing proper techniques and utilizing suitable tools, it’s possible to create personalized mugs. They will be high-quality and sure to captivate. Mug printing uses methods like screen printing, heat transfer, and sublimation. This guide covers the basics of mug printing. It details the most popular equipment, techniques, and their uses.

What is Mug Printing?

Mug printing transfers designs onto mugs. It makes them personalized or branded items. It uses various printing techniques. Create a design that combines long-lasting quality with aesthetic appeal. It must withstand regular use and washing. The printed designs can range from simple logos and text. They can go to intricate images and photographs. Mug printing uses several techniques. Each has different advantages and is suited for various uses.

Methods Involved in Mug Printing:

When it comes to printing on mugs, there are several methods available, each with its own specific requirements and advantages.

1. Sublimation Printing

Sublimation Printing transfers a design onto a mug. It uses sublimation ink and heat. It would help if you had special sublimation paper and ink. Heat and pressure transform the ink into a gas, bonding with the mug coating. This process creates a vivid, long-lasting print on the surface.

2. Heat Transfer Printing

Heat transfer printing is like sublimation. However, this method employs a unique transfer paper and ink. We utilize heat and pressure via a heat press, similar to the one mentioned previously. The ink or adhesive on the transfer paper bonds with the surface of the mug due to the application of heat, resulting in a permanent image.

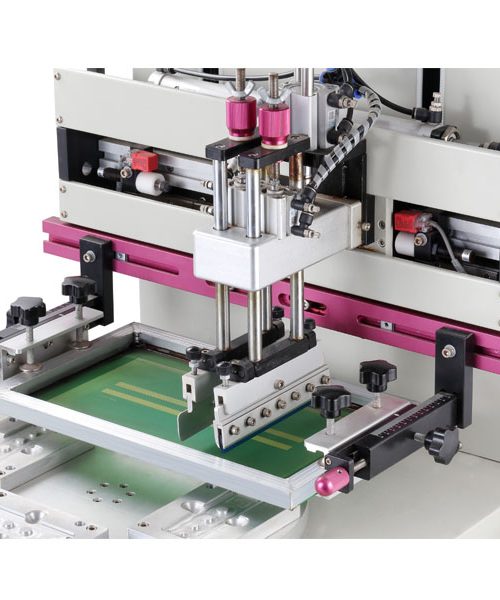

3. Screen Printing

It is also known as serigraphy or silk screen printing, is a process where ink is pressed through a stenciled mesh screen to transfer a design onto a flat surface. The screen is ready for printing by applying ink and positioning the stencil on the mug. You can use a squeegee to apply ink through a stencil onto the surface of a mug. Screen printing is most effective for creating a wide range of mugs with identical designs.

4. Vinyl Decal Printing

Vinyl decal printing includes trimming a design from adhesive vinyl. The process involves applying a vinyl decal to the mug surface and using a heat press to transfer the design. Vinyl decal printing facilitates the creation of complex designs, making it ideal for adding personalized names or messages to individual mugs.

5. Direct-to-mug Printing

Direct-to-mug printing, also known as digital printing or DTG (Direct-to-Garment) printing, uses a specialized digital printer to apply the design directly to the mug’s surface. This technique is perfect for high-resolution color images and photographs.

Exploring the Diverse and Innovative Techniques of Mug Printing

Mug printing techniques have gained popularity among industry professionals.

- They use various methods to print designs on mugs.

- Silk screen printing excels at producing large quantities.

- Digital printing suits small orders and intricate designs.

- Dye sublimation ensures vibrant colors and durability.

- Laser engraving creates precise, high-contrast designs.

- Industry professionals select techniques based on project requirements.

Currently, the most popular method of decorating mugs involves printing. The process is as follows: The ceramic powder is combined with selected colorants and a plasticizing agent. This mixture is then printed on gelatin-coated paper using traditional screen-printing techniques. The mixture passes through a fine mesh with a shaped mask. This creates a thin, even coating. Alternatively, a brush can be used for a more textured coating. Coating paper with photographic emulsion allows for photo printing and UV-curing images.

Once dried, the printed paper, also called a lithograph, can be stored indefinitely. The image is transferred to the mug by softening the litho in warm water. This removes the gelatin coat with the image from the paper. Following this, the mug undergoes a firing process at a temperature of 700-750°C (1,290-1,380°F; 970-1,020 K). This process softens the glaze and permanently embeds the image into the mug’s surface.

Commonly Used Mug Printing Technique:

The popularity of personalized gifts and customized products has led to an increase in mug printing. It paves the way for entrepreneurs and business owners to create unique and practical items. It helps entrepreneurs who want to start their businesses and small business owners who wish to expand their product range. Additionally, it is ideal for hobbyists who enjoy creating custom gifts. Mug printing provides the necessary tools to turn your ideas into reality.

Mug Printing Equipment:

There are different types of mug printing equipment. Depending on the printing methods, the types include automatic and commercial options.

Commercial Mug Printing Equipment:

This type of equipment refers to machines and tools designed for printing texts and images on ceramic mugs on a large scale for business and commercial production. Commercial equipment is suitable for medium to large-scale production and requires human operation and supervision. It provides flexibility, helping to meet tight deadlines. In the long run, commercial equipment is the most cost-effective choice, allowing businesses to streamline production and be more efficient by producing high-quality printed mugs. It is essential to understand the technical aspects and features of each type of equipment to gain good results in mug printing.

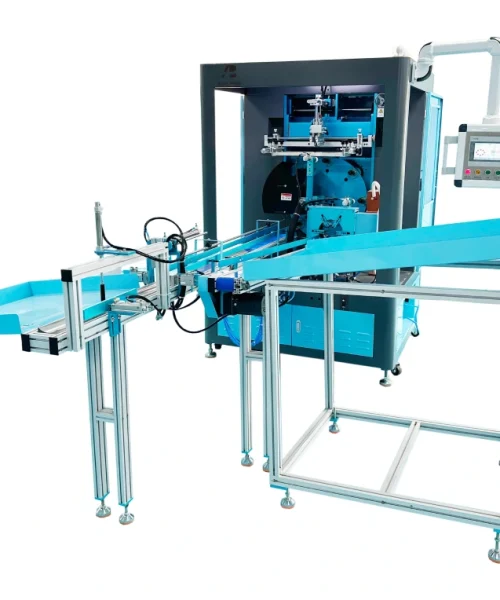

Automatic Mug Printing Equipment:

Automatic mug printing equipment is a sophisticated piece of machinery designed to automate the production of custom-printed mugs. These machines have the developed features and capabilities that streamline printing, making them ideal for high-volume production in commercial settings. This technology represents the pinnacle of printing and offers efficiency, precision, and scalability – making it well-suited for businesses specializing in customizing and producing mugs.

Best Mug Printing Equipment:

Circuit Mug Press

This is an easy heat press circuit mug press. It is specially designed for customizing mugs. It enables one to transfer infusible ink designs onto mugs. The best thing about it is that it involves high-quality, long-lasting prints. They actually get embedded into the mug and not just sit on the surface.

The mug press uses sublimation printing. It works with the circuit’s infusible ink. The process starts by making a design in the circuit design space. Then, the design is cut from infusible ink transfer sheets or drawn with infusible ink pens. Once the design is ready, it is attached to a sublimation-ready mug. The mug is then put in a sublimation mug press. Applying heat and pressure transforms the sublimation ink into a gaseous state. The gas bonds with the mug’s coatings. This results in a bright and durable design. It can withstand regular use and washing.

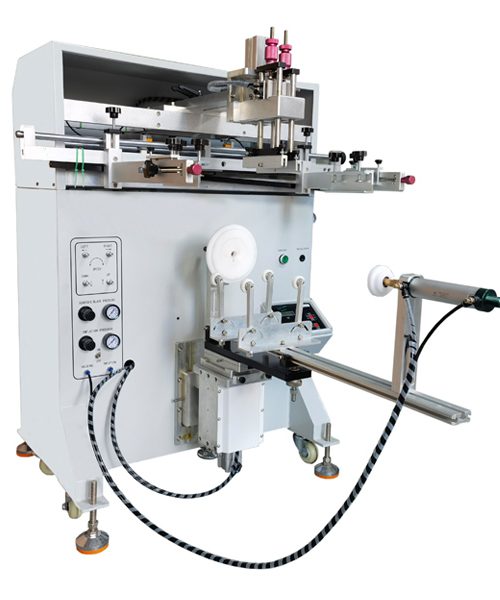

Heat Press Mug Printing Machine

Heat press machines are essential tools. They transfer custom designs onto mugs using heat and pressure. This process is applied widely in sublimation and heat transfer printing.

Heat-press mug printing machines use heat and pressure. They transfer designs from paper to the mug surface. The process begins by wrapping the printed paper around the mug. It ensures that the design faces the right way. The mug is nested inside the heat press and heated at the required temperature and pressure settings. When you turn on the machine, it heats the heating element to the set temperature, usually 350°F to 400°F, while pressing the transfer paper firmly against the mug by pushing it. The heat and pressure turn the ink into a gas. The gas then goes into the mug coating, embedding the design. The controlled environment ensures the design transfers evenly. As a consequence, the prints are vivid, long-lasting, and of superior quality. They resist fading and peeling.

The Mimaki Mug Printing Machine

The Mimaki mug printing machine uses a unique printing method. It is known as direct-to-object (DTO) printing. The Mimaki mug printing machine revolutionizes mug printing with its direct-to-object printing technology. It eliminates the need to buy transfer papers and coatings. It is also quite user-friendly and can deliver a fine final product. We use it in doing individual personalization for customers, branding our mugs, and doing retail sales. Mimaki printers deliver high definition on the mug with long-lasting results.

It adds color using advanced inkjet systems. The ink is applied to the surface and quickly cured with ultraviolet light. This method ensures bright colors and clear details. The prints are durable and stick firmly onto the surface of the mug. DTO printing is very efficient and offers quick turnaround times. It is also versatile and capable of working on a wide range of surfaces, including glass, ceramics, metal, and more, extending beyond just mugs.

Automatic Mug Heat Press Machine

An automatic mug heat press machine is a specialized piece of equipment. It uses pressure and heat to imprint designs onto mugs. Mug heat press machines are crucial tools for businesses and service providers. They want efficient, high-quality mug printing. The machines automate the printing process. They also add advanced control features. They ensure consistent results. Custom mug production scales up with improved workflow efficiency.

Once-Tech is dedicated to providing efficient and precise automated printing solutions. Our Automatic Mug Heat Press Machine is not only suitable for mug printing but also features an innovative design that allows for diameter adjustments, making it capable of printing on various curved products. Whether it is plastic, glass, or metal, this equipment ensures exceptional printing results. With advanced technology and reliable performance, Once-Tech’s automated curved printing equipment empowers various industries to achieve high-quality custom printing, meeting diverse market demands. If you have any special needs, please contact us directly. We will recommend the most suitable product for you according to your actual needs.

Conclusion

Mug printing customizes ceramic mugs with designs, images, and text, making them unique and meaningful. This article covers various printing methods. These include sublimation, heat transfer, screen printing, vinyl decals, and direct-to-mug printing. Each method has its own advantages. It also highlights the popularity of personalized gifts and promotional items. The article discusses different types of equipment. It focuses on automatic and commercial options. These options cater to various production scales and needs. For high-volume, precise printing, automatic machines are ideal. They are cost-effective for medium to large-scale operations.