In the cosmetics industry, the look of product packaging is crucial. Screen printing is popular for decorating bottles. It offers durable, high-quality finishes. This article will explore the top 10 cosmetic bottle screen printing machines. We’ll highlight five machines from Once-Tech and five from other leading manufacturers. Each machine has unique features to meet various production needs.

1. 2-Color Servo Screen Printing Machine (Once-Tech)

This machine is a versatile powerhouse. It can make two-color prints with exceptional precision. It’s a fully automatic screen printer. It can handle various shapes and surfaces. So, it’s suitable for many uses. The machine allows for choosing different inks. These include high-temperature, UV, and LED inks. They ensure adaptability to many printing needs. The high-precision splitter and servo control show the machine has advanced technology. This tech ensures high-quality prints every time.

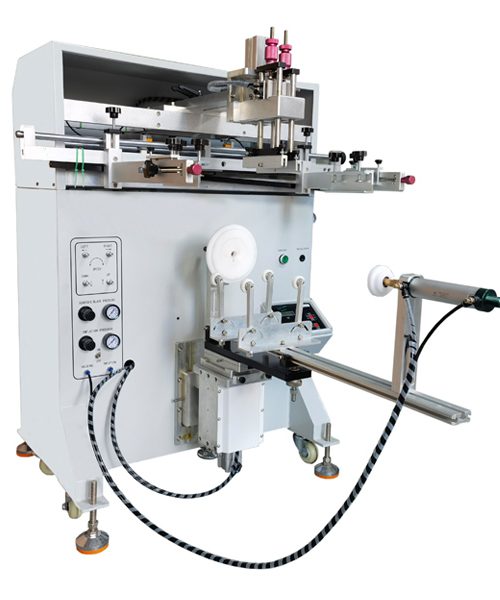

Servo Rotarytable Screen Printing Machine

2. Round Bottle Screen Printing Machine 600 (Once-Tech)

The Round Bottle Screen Printing Machine 600 is a semi-automatic printer. It is for cylindrical objects like bottles and containers. It has a max print diameter of 200mm. It is pneumatically driven, so it runs smoothly. The machine has a microprocessor for precision. It also has a quick tooling changeover for versatility. It has a synchronized bottle inflation system with a regulator. All controls are conveniently on the front panel. This machine is best for small to medium production runs. It offers a balance of speed and quality.

Cylindrical Screen Printing Machine

3. Round Bottle Screen Printing Machine (Once-Tech)

This machine is for high-quality printing on round bottles. It’s a staple in industries like beverages, cosmetics, and pharmaceuticals. It can fit many bottle sizes. It ensures versatility across product lines. The machine has an advanced servo indexing system. It provides precise location control, which is critical for different color prints. It also has an integrated UV curing system. It instantly cures the ink. It makes for vibrant and durable prints. The machine has a modular design. It allows for easy maintenance and quick part replacement. It minimizes downtime and maximizes productivity.

Cylindrical Screen Printing Machine

4. 1-Color Automatic UV Bottle Screen Printing Machine (Once-Tech)

The 1-color Automatic UV Bottle Screen Printing Machine is designed for simplicity and efficiency, making it ideal for high-volume production environments. It has an automatic loading and unloading system. It reduces manual labor and raises output. The machine’s UV curing system ensures quick drying. It also improves the print’s resistance to fading and wear. It is compatible with many inks and substrates, making it versatile for printing needs. Also, the machine is small. So, it’s a good choice for the cosmetic printing industry with limited space.

Cylindrical Screen Printing Machine

5. 1-Color Tube Screen Printing Machine (Once-Tech)

The 1-Color Tube Screen Printing Machine is a display of precision engineering. It meets the high standards of tube printing. It’s a machine that can handle many tube sizes and lengths. It’s automatic and suits many industries, from cosmetics to pharmaceuticals. The machine has a high-speed rotary indexing system. It ensures fast and accurate prints. The prints use UV curing. They are vivid and resist smudging and fading. The machine has a user-friendly interface. Its setup is quick. It allows for easy operation, even for those new to screen printing.

Cylindrical Screen Printing Machine

6. Model T8-SS Fully Automatic Cosmetic Jar Screen Printing Machine (Systematic Automation)

It is the Model T8-SS. It is a Fully Automatic Cosmetic Jar Screen Printing Machine. It is high-speed and servo-driven. It is for precision printing on cosmetic jars. It has a UV curing system. It has a touch screen for ease of use. It can quickly switch between different jar sizes. It has safety mechanisms. They ensure high standards for different color printing. It prints at a rate of 3,600 parts per hour. It is ideal for large-scale cosmetic packaging. Its modular design allows for customizations. These include pre-treatment stations and optical registration systems. They cater to a wide range of printing needs in the cosmetic industry.

7. Model F1-DC Precision Screen Printer (Systematic Automation)

The Model F1-DC Precision Screen Printer is a tough and versatile machine. They are designed for high-quality screen printing. It is for printing on cylindrical products, such as cosmetic bottles. It has a 100% air operation system. It ensures it cannot overload or burn out. This makes it a reliable choice for continuous production. The machine can handle about 3,600 prints per hour, depending on the product. It offers a quick changeover between products in seconds making it ideal for both short runs and high-volume production. It has a heavy-duty construction. It has micro-adjust tables, variable squeegee speed, and flood bar speed. It also has a multicolor registration system. This enables comprehensive coverage of diverse objects with panoramic images.

8. BottleJet Cylindrical Inkjet Printer (Engineered Printing Solutions)

The BottleJet is a rotary UV LED inkjet printer by Comec Digital. It is for printing and decorating cylinders and cones. It can print at resolutions up to 1200 dpi. It has adjustable supports for different product sizes and shapes. It uses up to 3 RICOH Gen 4 print heads. It allows for precise and fast printing. The BottleJet has advanced UV LED technology. It can print on various curved surfaces. It makes it ideal for cosmetic businesses that want to add a personal touch to their products.

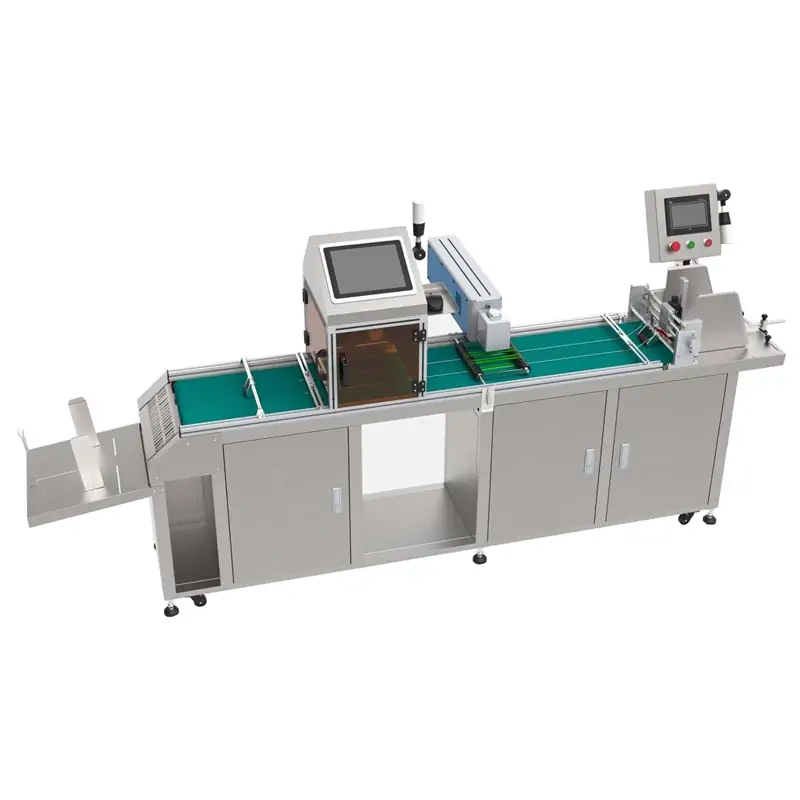

9. UV Piezo Printing Machine for Cosmetic Containers (Shanghai Loobjet Information Technology Co., Ltd.)

The UV Piezo Printing Machine is state-of-the-art. It is a solution for branding cosmetic containers. It offers high precision and efficiency. This machine uses advanced piezoelectric on-demand inkjet technology. It can handle many types of cosmetic containers. These include bottles, tubes, caps, and more. It stands out for its ability to make full-color prints well and fast. Production capabilities undergo significant enhancement. UV curing transforms the ink into a dry state. This gives durable, vibrant prints that can withstand handling and use. This technology is great for cosmetic companies. They want to build or improve their brand identity. They want to do it with clean, attractive, and unique container designs.

10. Omso Imprex

The Omso Imprex is an advanced screen printing machine designed for precise and versatile printing on plastic tubes. It ensures full 360-degree image coverage with exceptional accuracy. This machine accommodates various tube sizes and shapes, making it ideal for the cosmetic and pharmaceutical industries. With its rapid changeover capabilities, the Imprex can achieve an impressive throughput of up to 5,000 prints per hour, depending on the product. The machine operates with a high level of automation, reducing manual intervention and ensuring consistent quality. Its robust construction and reliable performance make it a perfect choice for both small and large-scale production, offering flexibility, efficiency, and top-notch printing results.

Conclusion

Choosing the right screen printing machine for cosmetic bottles is crucial. It’s for high-quality, durable, and appealing packaging. The machines highlighted offer various features to meet different production needs. The machines are high-speed and support different colors. But, some are for single-color. Each type has unique advantages. Picking the correct machine can help manufacturers. It can improve their production. It can reduce the cost of manufacturing and boost the brand’s market presence with better packaging.