Pad printing is a versatile printing process that can be used to print on a wide range of surfaces and materials. This printing technique is commonly used to print logos, graphics, and text on various products, including electronics, medical devices, and promotional items. In this blog post, we’ll take a closer look at how pad printing works and the benefits of using this printing method.

What is Pad Printing?

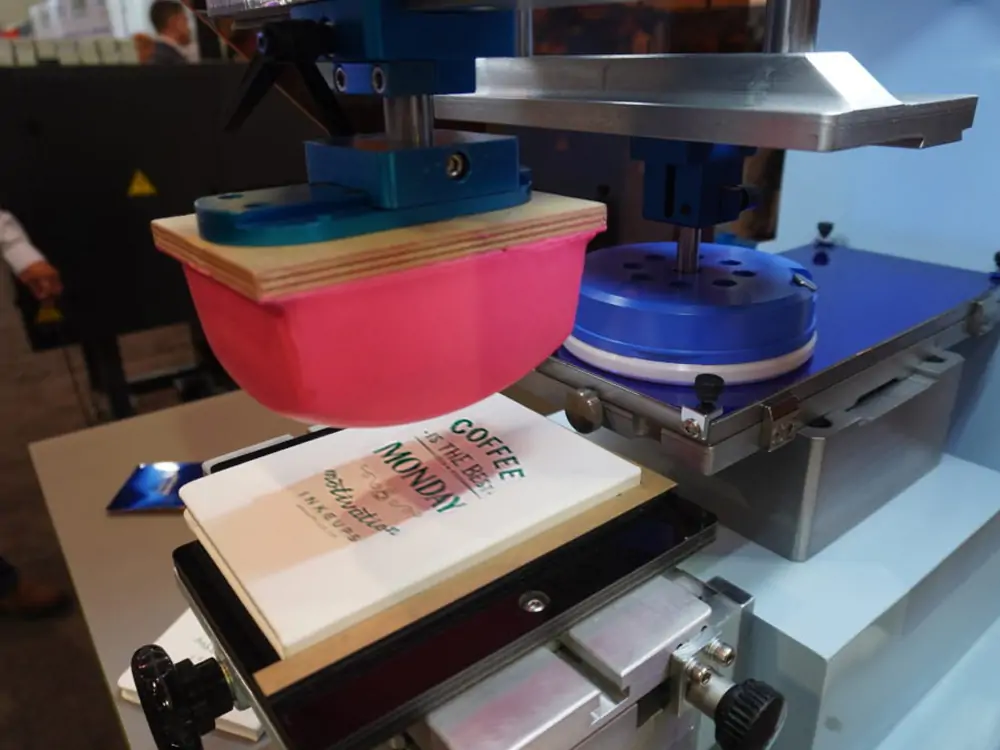

Pad printing is a printing process that uses a soft silicone pad to transfer ink from an etched plate onto the surface of a product. The process involves four main components: the printing plate, the ink, the silicone pad, and the product to be printed.

How Does Pad Printing Work?

The pad printing process starts with the design of the printing plate. The plate is etched with the desired image, logo, or text using a chemical process. The etched areas of the plate hold the ink, while the un-etched areas do not. The plate is then coated with ink, which fills the etched areas.

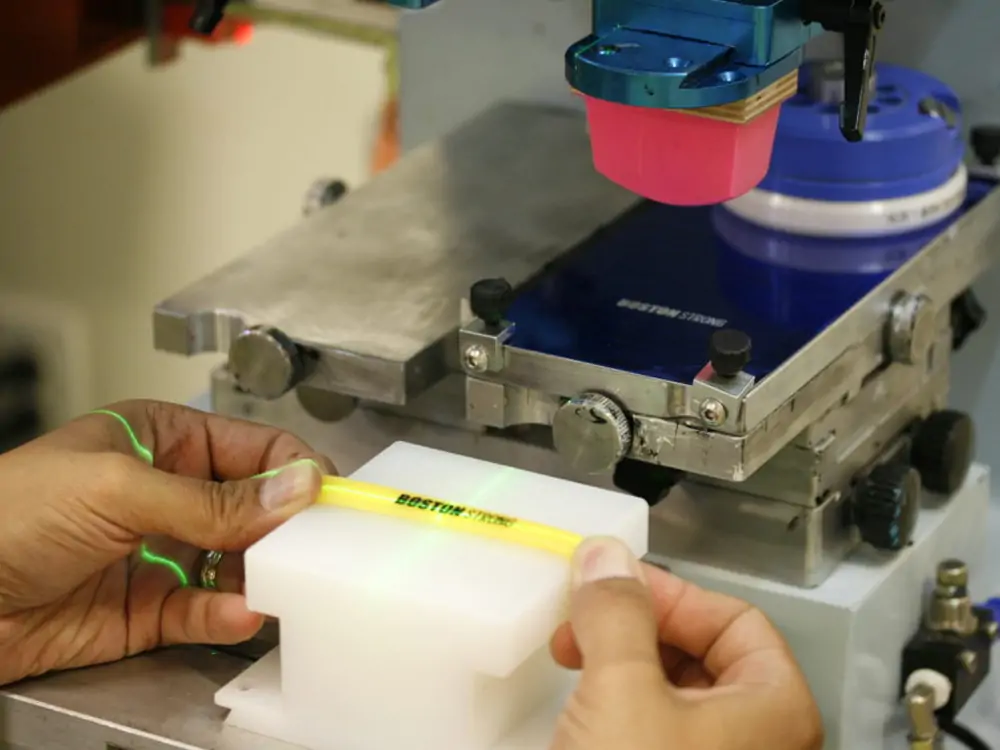

Next, the silicone pad is lowered onto the inked plate, and the ink adheres to the pad. The pad is then lifted off the plate, and the ink is transferred to the surface of the product to be printed. The silicone pad conforms to the shape of the product, allowing for precise and accurate printing on irregular or curved surfaces.

The printing process is repeated for each product to be printed, with the pad being re-inked between each print. The ink is cured using heat or UV light, which ensures that the print is permanent and will not smudge or fade over time.

What Pad Printing Supplies Do I Need?

To start a pad printing operation, you will need various supplies and equipment. Here’s a list of the essential pad printing supplies you will need.

Pad Printing Machine

This is the primary piece of equipment used for pad printing. It includes features like a printing plate holder, ink cup, and pad mechanism. The machine should be selected based on the size and shape of the objects you plan to print.

Printing Plates or Clichés

These are etched plates made from various materials (such as steel or polymer) that contain the design or image to be printed.

Ink Cups and Rings

The ink cup holds the ink and delivers it to the printing plate during the printing process. It helps to ensure precise and consistent ink application.

Silicone Pads

Silicone pads are flexible and are used to pick up the ink from the printing plate and transfer it to the object being printed. Pads come in various shapes and sizes to accommodate different designs and surfaces.

Ink

Pad printing inks are specially formulated for adhesion, flexibility, and durability. They can be solvent-based, water-based, or UV-curable depending on the application and material being printed.

Solvent or Cleaner

This is used to clean the ink cups, plates, and other components of the pad printing machine. The type of solvent or cleaner will depend on the type of ink you are using.

Substrates or Printing Surfaces

These are the objects or materials that you will be printing on. They can be made of various materials like plastics, metals, glass, ceramics, and more.

Fixtures or Jigs

These are used to hold the objects in place during the printing process, ensuring consistent placement and registration of the print.

Drying Equipment (optional)

Depending on the type of ink used, you may need a drying system like UV lamps for curing UV-curable inks.

Safety Equipment

This may include gloves, safety glasses, and ventilation systems to ensure a safe working environment, especially when handling inks and solvents.

Basic Tools and Accessories

These may include spatulas for ink mixing, tweezers for handling small parts, and other tools for maintenance and setup.

Consumables And Spare Parts

Keep a stock of consumables like pads, plates, and inks. It’s also a good idea to have spare parts on hand in case of any machine maintenance or repairs.

Benefits of Pad Printing

Pad printing offers several benefits over other printing methods, including:

Versatility

Pad printing can be used to print on a wide variety of surfaces and materials, including plastic, metal, glass, and ceramics. This makes it a popular choice for printing logos and graphics on a range of products, from toys to medical devices.

Precision

The soft silicone pad used in pad printing allows for precise and accurate printing on irregular or curved surfaces. This makes it possible to print on products with complex shapes or designs, such as computer keyboards or electronic devices.

Durability

The ink used in pad printing is highly resistant to fading, smudging, and wear. This makes it ideal for printing on products that will be exposed to harsh environments or frequent handling, such as remote controls or medical equipment.

Cost-Effective

Pad printing is a cost-effective printing method, especially for small to medium-sized runs. The process requires minimal setup time and can be used to print multiple colors in a single pass, which reduces the time and cost of printing.

Applications of Pad Printing

Pad printing is used in many industries, including:

Electronics

Pad printing is commonly used to print logos and text on electronic devices, such as remote controls, gaming controllers, and mobile phones. The precision and versatility of pad printing make it an ideal choice for printing on small, complex surfaces.

Medical Devices

Pad printing is used to print on medical devices, such as syringes, catheters, and surgical instruments. The durability and resistance to wear and tear of pad printing make it ideal for printing on products that will be exposed to harsh environments and frequent handling.

Promotional Products

Pad printing is often used to print logos and graphics on promotional products, such as pens, keychains, and mugs. The cost-effectiveness and versatility of pad printing make it a popular choice for small to medium-sized runs of promotional items.

FAQs About Pad Printing

Pad printing is a versatile printing process that involves transferring a 2D image from a printing plate onto a 3D object. It is commonly used for applying logos, labels, and designs onto irregularly shaped surfaces.

A silicone pad, which is flexible and can conform to the shape of the object being printed, picks up ink from an etched printing plate. The pad then transfers the ink onto the surface of the object.

Pad printing offers high resolution, durability, and the ability to print on irregularly shaped objects. It is suitable for a wide range of materials including plastics, metals, glass, ceramics, and more.

Pad printing can be used on various materials including plastics, metals, glass, ceramics, wood, leather, and some fabrics. It’s particularly effective on curved, uneven, or textured surfaces.

Pad printing inks are specially formulated for adhesion, flexibility, and durability. They can be solvent-based, water-based, or UV-curable depending on the application and material being printed.

Yes, pad printing can be used for high-volume production runs. It is a cost-effective method for producing large quantities of items with consistent quality.

Yes, multi-color designs can be achieved using multiple printing plates and pads. This allows for intricate and colorful designs on the same object.

Pad printing may not be suitable for very large print areas or extremely detailed images. Additionally, it may not be the best choice for very high-speed production lines.

The environmental impact of pad printing depends on the specific inks and solvents used. Water-based and UV-curable inks are generally considered more environmentally friendly than solvent-based inks.

Yes, it is possible to set up a pad printing operation in-house with the right equipment, training, and supplies. However, it’s important to consider factors like space, ventilation, and safety measures.

Pad printing is used in a wide range of industries including electronics, automotive, medical devices, promotional products, toys, sporting goods, and more.

When choosing a pad printing machine, consider factors like the size and shape of the objects you’ll be printing, the desired production volume, and the complexity of your designs. It’s also important to select a reputable supplier.

Conclusion

Pad printing is a versatile and cost-effective printing method that can be used to print on a wide range of surfaces and materials. The precision and accuracy of pad printing make it an ideal choice for printing on small or irregularly shaped surfaces, while the durability and resistance to wear and tear make it ideal for printing on products that will be exposed to harsh environments or frequent handling.

If you’re interested in pad printing, contact a professional printing service to learn more about how this printing method can benefit your business.