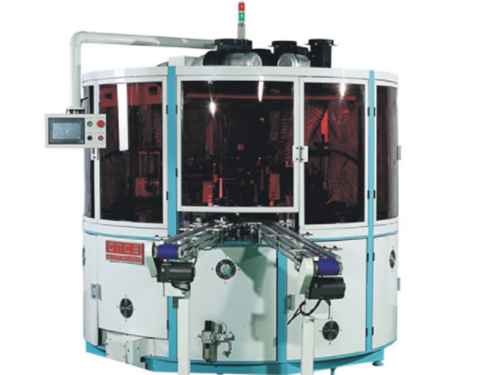

Automatic screen printing machine

Flashing

Quality compressor

Conveyor dryer of the right size

Aviation line

Electrical drops

Automatic screen printing management program

How to choose the correct automatic screen printing machine: How many color stations do I need?

You need an automatic screen printing machine that is easy to operate, set up, and maintain. One of the biggest misunderstandings about automatic screen printing machines is that bigger is better. However, a simple, small automatic screen printing machine can sometimes bring you the best return on investment.

Since customers who enter automatic screen printing shops are generally unwilling to pay the screen setup fee, many shops have limited colors for automatic screen printing. Most automatic screen printing machines work between 1 and 3 colors. Therefore, it does not make sense to invest money in large-scale automatic screen printing machines that cannot be fully utilized.

When deciding how many colors and positions to choose, there is a simple rule of thumb: buy an automatic screen printing machine that can cover about 80% of your work. These will be your ideal choice and can bring revenue to your store. Most auto printing machines can effectively use 4-color Mini-Trooper automatic screen printing machines with a diameter of only 8 feet. If a job is beyond the scope you can print on an automatic screen printing machine; it is worth considering whether the time and effort spent on automatic screen printing allow you to get enough profit from this job.

A suitable automatic screen printing machine can increase your workflow

- A good criterion for automatic screen printing is adding an automatic screen printing machine to handle the increased workflow. Who wouldn’t like to cut the production time in half while reducing the printing workload at the same time? Adding an automatic screen printing machine can enable you to perform automatic screen printing at least four times faster, making your business easier.

- The automatic screen printing machine can print large-screen jobs. You can do more work and take on more customers. Automatic screen printing machines provide unprecedented opportunities for new automatic screen printing jobs. Using a manual printing machine may take you several days to print 100 T-shirts. If there is an unexpected situation, you must adjust it to complete the large-scale work in time. However, automatic screen printing machines allow you to complete the work at lower labor costs. This will reduce the fatigue of the automatic printing machine and ensure that you can get high-quality automatic screen printing at any time of the day.

Now that you know the importance and precautions of automatic screen printing machines, here are some best-selling auto printing machines that are worth buying.

COBRA™ Automatic Screen Printing Press

M&R’s COBRA™ automatic screen printing machine is the standard that combines high-quality components, durable craftsmanship, and high-speed production in one machine. COBRA series presses provide operators with the time-saving features needed for quick setup-electric print head, tool-free wiper/shovel angle adjustment with air brake, pneumatic frame lock, and independent wiper digital display Knife/water injection speed.

STRYKER™ Automatic Oval Screen Printing Press

M&R’s Stryker sets the standard for oval screen printing machines. Compared with similar rotary automatic screen printing machines, its oval design occupies less floor space, thereby making more efficient use of the available production area. Stryker is equipped with three print format sizes, which can be expanded from 10 to 52 workbenches to optional print head positions. This automatic screen printing machine can be customized for almost any production requirement, floor layout, or workshop scale. The high-quality, smooth-running servo drive indexer can provide a fast and accurate single index or double index, making Stryker ideal for cut pieces and overall printed garments. The 80×110 model can print up to 132 x 110 cm (52 inches x 43.5 inches) with alternate print heads!

CHALLENGER® III Automatic Screen Printing Press

Challenger® revolutionized automatic screen printing in the 1980s because the Challenger once dominated the industry. M&R’s Challenger III automatic screen printing machine combines innovative features (such as M&R’s electronically adjustable Ink Dip™ ink recovery system) and more than 25 years of M&R automatic screen printing technology to provide excellent speed and the best creativity. It was expanded on a traditional basis. Challenger III’s indexer can achieve double indexing in one uninterrupted movement, eliminating the pause between indexing, thereby increasing the production speed of super large workpieces.

GAUNTLET® III Automatic Screen Printing Press

Gauntlet III is M&R’s multifunctional, high-volume, medium-sized automatic screen printing machine. It offers 10-18 colors, and the maximum standard image area is 48 x 55 cm (19 inches x 22 inches). The Gauntlet III automatic screen printing machine has a print head driven by a fast and reliable electric motor. The print head has a calibrated, tool-free, click-stop four-corner non-contact setting to achieve fast and accurate screen leveling. The auto printing machine includes tool-free front and rear printing stroke adjustment devices to achieve versatility and high productivity.

SPORTSMAN® EX Automatic Screen Printing Press

M&R’s Sportsman®EX automatic screen printing machine provides extraordinary value and quality at an ultra-low price. Sportsman EX 4045 is available in 6-color, 8-color, 10-color, and 12-color models with a maximum image area of 41 x 46 cm (16 inches x 18 inches). Sportsman EX 5050 is suitable for 6-color, 8-color, 10-color, and 12-color models, with a maximum image area of 51 x 51 cm (20 inches x 20 inches). The Sportsman EX 5070 with dual index function has a dual index function and is specially designed for piece printing. It is available in 6, 8, 10, and 12-color models with a maximum image area of 51 x 71 cm (20 inches x 28 inches).

CHALLENGER® II & II OS Automatic Screen Printing Press

Challenger® II and Challenger® II OS are M&R’s most affordable large-format high-performance automatic screen printing machines. Designed for quick set-up and high-speed production, they have time-saving output enhancements that make them excellent performance in any automatic screen printing plant. Challenger II is available in 10, 12, 14, 16, and 18 color models with a maximum image area of 50 x 70 cm (20 inches x 28 inches). Challenger II OS is available in 8, 10, and 12-color models, with a maximum of 70 x 100 cm (28″ x 39″) and the most prominent image area. All Challenger II OS models are equipped with sizeable heavy-duty pallet support arms and extra-large pallet leveling brackets. It has excellent rigidity and stability when cutting and printing. All Challenger II automatic screen printing machines have servo-driven indexers, electric print heads, and multiple printing stroke functions.

DIAMONDBACK E™ Automatic Screen Printing Press

Diamondback E™ is an evolution of the famous Diamondback series product line. This series of products has a multi-functional, affordable automatic screen printing machine for entry-level users to bring a full-featured servo index drive automatic device. With electric print heads, Diamondback E is the best choice for step-down entry-level automatic screen printing machines. There are 6, 8, or 10 colors to choose from. The maximum image area of the diamond vest E is 41 x 46 cm (16 inches x 18 inches), and it can accept a screen frame of up to 58 x 84 x 5 cm (23 inches x 33 inches x 2 inches).

The Diamondback E screen printer is equipped with an electric print head that provides smooth and consistent print carriage movement. At the same time, a side frame holder with pneumatic clamps enables fast screen printing, and no special adapters are required to hold the rollers securely. It can provide excellent stability on various screens. The pneumatic wiper/overflow bar fixture has a calibrated tool-free angle adjustment function. A pneumatic wiper pressure regulator with a pressure gauge on each print head provides excellent control of printing parameters. The high-resolution touchscreen control panel has easy-to-use icon-based logic and a built-in tutorial screen that effectively puts the user manual at the operator’s fingertips.

VICTORYONE® Automatic Oval Screen Printing Press

M&R’s aggressively priced VictoryOne is the most affordable oval automatic screen printing machine in the industry. It can be used with two different M&R Digital Squeegees for fast mixing and automatic screen printing. The basic modules of VictoryOne’s 22 sites can be expanded in 6 site increments to create configurations of 28, 34, 40, 46, 52, 58, and 64 sites. All stations except the four stations at both ends of the auto printing machine can support the print heads, and these print heads must be configured in pairs. Otherwise, there are no restrictions on the print head placement, and any workstation can be opened. The flexibility of VictoryOne allows it to be tailored to almost any production requirement. It also allows the automatic screen printing machine to be placed in a position where the carousel cannot be pressed.

SPORTSMAN® EXG Automatic Screen Printing Press

M&R’s Sportsman®EXG automatic screen printing machine is high-speed, with a maximum image area of 51 x 51 cm (20 inches x 20 inches), a small footprint, and a reasonable price. It is available in 12-color and 14-color models and offers a variety of options. A series of standard functions, starting with a servo-driven indexer, combine higher automatic screen printing speed with excellent smoothness, consistency, and longevity. Variable speed electric print head can achieve smooth printing stroke and superior control. The central disconnected contact can realize fast and incremental single printing; adjust the control levers of all radio stations simultaneously; the color touch screen control panel with a graphic display can provide on-board self-diagnosis, real-time production data, and most of the user’s press functions Friendly control.

DIAMONDBACK L™ Automatic Screen Printing Press

Diamondback L™ is part of the Diamondback series of the M&R series. This series is versatile and affordable. It is an entry-level automatic screen printing machine. This is a six-color automatic screen printing machine with a maximum of 35 x 28 cm (14 inches x 11 inches). The fixed screen stand can accommodate a 51 x 61 inch (20-inch x 24 inches) screen frame. It is Unique, very suitable for manual shops that want to enter a limited space for automatic screen printing. At the same time, its high-speed servo system and 259 cm (8 feet 6 inches) diameter make it ideal for large shops interested in automatic screen printing machines, which require only a tiny space. And there are no labels, pocket printing, and smaller formatted images.

Excellent quality. Diamondback L’s heavy-duty casters make it easy to move around in the store or undisturbed when not in use.Diamondback L screen printing machine has a servo-driven indexer to ensure smooth and accurate travel; pneumatic screen clamps can promote rapid loading. No special adapters are required to fix the roller frame to provide excellent stability on various screens. Each screen printing machine has a pneumatically driven print head. Pneumatic squeegee/overflow clamp, the angle can be adjusted without tools; pneumatic screen frame clamp; pneumatic scraper pressure regulator, each print head is equipped with a pressure gauge, which can control the printing pressure excellently.