Introduction

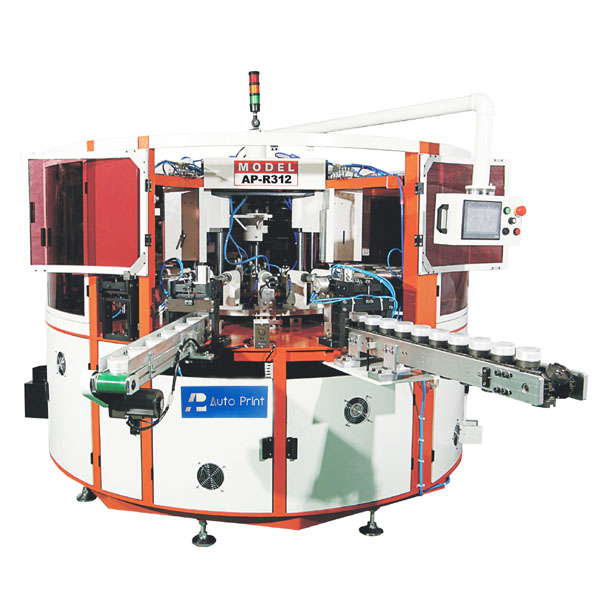

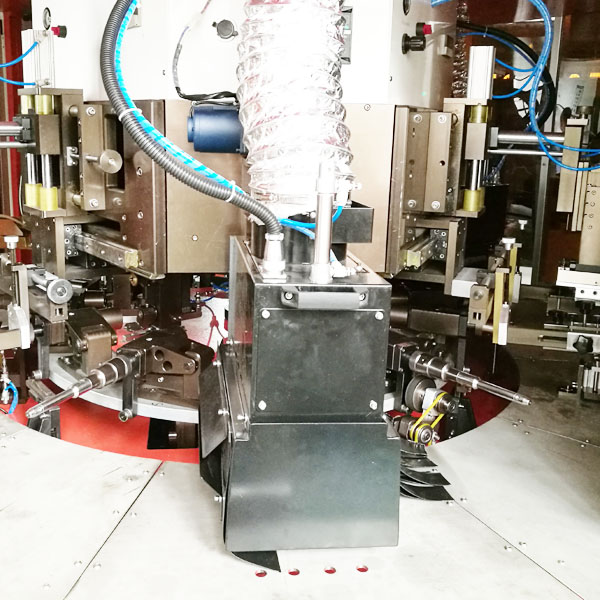

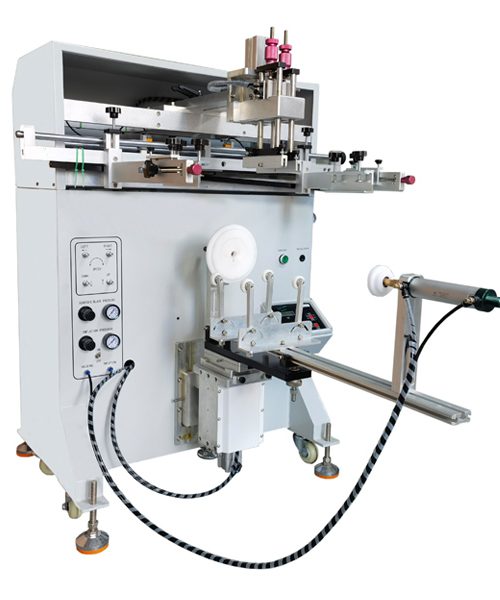

The AP-R312 is a fully automatic UV cosmetic tube, small glass container, plastic jar and air/oil filter screen

printing machine that offers increased productivity and unrivalled value for the money.

The AP-R312 is driven by a SANKYO rotary positioning drive system and features a SITI main drive motor

with a barrel cam.

The UV screen printing inks are automatically cured with high powered UV lamps positioned after each

printing station. After loading of the flexible or rigid tubes there is a pre-flame treating station and de-ionizing /

cleaning station (optional) to ensure quality printing results with fewer defects.

The AP-R312 system is equipped with intelligent UV curing units which are outfitted with high intensity

mercury UV bulbs.

Specifications

| Model NO.: | AP-R312 |

| Print product size: | dia10-60, L30-250mm |

| Max. print area: | (10-80mm) x (20-200mm) |

| Max. printing speed: | 60 pcs/min |

| Registration tolerance: | +/- 0.2 (except product tolerance) |

| Screen Drive: | Servo motor driven |

| Print Station Drive: | Servo motor driven |

| Flame treating system: | 1 unit |

| Print head: | 3 units |

| Stations: | 12 stations |

| UV system: | 3 unit Fusion UV system |

| UV lamp power: | 1.8 KW/UNIT |

| Deionizing device: | 1 unit CIMCOR Brand |

| Motor: | ITALY SITI |

| Control system: | OMRON PLC & Touch Screen |

| Pneumatic parts: | Japan SMC |

| Electrical supply: | 380V/480V 3phase 50Hz/60Hz |

| Air requirement: | 6-8bar |

| Power consumption: | 15 KW |

| Machine dimension (LxWxH): | 5000 x 2800 x 2350 mm (including electric cabinet) |

| Crated size(LxWxH): | 2300 x 2300 x 2350 mm |

| Weight: | 3500 KG |

| Crated weight: | 3800 KG |

Reviews

There are no reviews yet.