Screen printing has been one of the most popular ways to create high-quality prints on different surfaces. From signage and promotional stuff to garments and textiles. With a rise in the demand for screen printing, businesses and individuals are increasingly investing in automatic screen printing presses. But is it worthwhile to invest in new automatic screen printing equipment? Or would it be wiser to use an automatic screen printing machine?

Well, those are the questions that we’d try to address in this blog by weighing the pros and cons of both these options. But before we go into the specifics, let’s first discuss what an automatic screen printing press is all about.

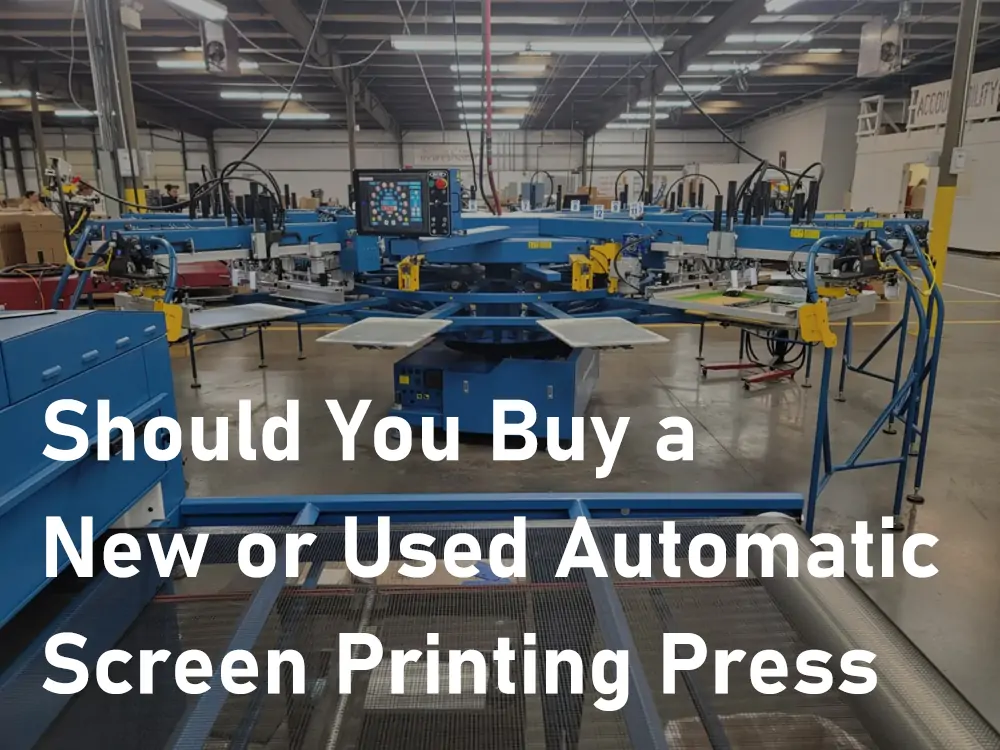

What Is An Automatic Screen Printing Press?

An automatic screen printing press is a device that helps with the automation of the screen printing process. So it allows for much quicker production and higher output than manual methods. These machines usually comprise screen holders, a printing table, squeegees, and a control panel that you can use to set and manage functions.

Now that you know what an automatic screen printing machine is. Let’s explore the advantages and disadvantages of a new automatic screen printer machine.

Benefits of Owning An Automatic Screen Printing Machine

The advantages of owning an automatic screen printing machine are manifold. These machines offer business owners an edge in consistency, efficacy, and production speed. Thus, you can handle larger volumes of work with minimal human intervention by automating the printing process. So, if you run a startup, an automatic screen printing press will allow you to meet growing demands and deadlines.

Also, an automatic screen printing press offers another major advantage by reducing labor costs. You would need fewer operators to run an automatic screen printing machine than manual printing. So you can save significantly on labor expenses over a period.

Moreover, you’d get consistent quality with an automatic screen printing machine. The accuracy and precision of these machines play a key role in substantially minimizing the risk of errors and waste. It must be for businesses that seek to deliver high-quality prints to their customers. So an automatic print machine would help you achieve consistent results across a large batch of prints. It can ensure customer satisfaction and enhance your reputation.

Advantages & Disadvantages of Purchasing A New Automatic Screen Printing Press

One major advantage of buying a new automatic screen printing press is the assurance of reliability and performance. A new automatic screen print machine will have warranties and guarantees like other machines. It assures you that you’re putting your hard-earned money into a reliable tool. Moreover, new presses usually come with the latest technology. So it can ensure you get the utmost efficiency, precision, and ease of use. This not only enhances productivity but also the print quality.

But, like any other equipment, buying a new automatic screen print machine also has certain considerations. The biggest disadvantage of buying a new screen printing press is the higher cost. You might have to shell out a significant amount to buy new equipment. Especially if you plan for models with advanced features. Such a high initial investment might not be economically viable for small businesses or startups with limited financial means. Moreover, the availability of new models is often limited, which can lead to a longer lead time for delivery.

But if you own a small printing business, you need not be worried as this is where an automatic screen printing press comes into the picture.

Advantages & Disadvantages of Purchasing A Used Automatic Screen Printing Press

Unlike buying new equipment, purchasing a used automatic screen printer can be much more affordable. Used machines are almost always priced lower than new machines. This allows businesses to save a large amount of money initially. Moreover, the secondary market for screen printing machines is large. This allows buyers to choose from various options. Businesses always have the opportunity to buy a printing machine best suited to their needs without going over their budgets.

But, there are also downsides to purchasing used screen printing machines. The condition of the equipment is the most important. As with any other equipment, used printing machines will have undergone wear and tear. This will entail adequate maintenance and timely repairs to restore the machine’s optimal working capacity. Not only is it time-consuming but also resource and budget-intensive.

So, if you buy a used automatic screen printing press, you must examine the equipment thoroughly. Always ask for a demonstration before you buy it.

Moreover, it is possible that used printing presses might not be compatible with the latest technology. Compared to the newer models, it will significantly limit their efficacy and overall output.

To ensure you face the smallest issues after purchasing a used automatic screen printing press, always buy from sellers or dealers with a proven track record at selling this equipment and offer warranties or guarantees on their products. This offers no certainty that the products you buy will have an extended life cycle. But it still gives you protection and a good recourse if you face any unexpected issues later.

You can also consider purchasing refurbished equipment. As refurbished presses undergo professional restoration and ample testing, you can rest assured that they will function as well as a new one.

Should You Buy A New or Used Automatic Screen Printing Press?

There’s no fixed answer to this question. The ideal choice depends largely on the buyer’s specific needs, priorities, and goals. So, if you have limited funds and the budget is an issue, you can consider buying a used press.

On the other hand, if you own a large business relying on the latest features for high performance, consider investing in a new automatic screen printer. When purchasing an automatic screen printer machine, analyze whether the features and capabilities align with your production needs. Different models will offer varying printing speeds, colors, and the capacity to care for different substrates and their sizes. It’s also possible that a used machine might offer greater functionalities than a new printing press you plan to buy. Therefore, it’s vital to conduct thorough research and evaluate your requirements. This will help you make an informed decision while choosing between a new and a used automatic screen printing press.

Finally, the last aspect you must consider is the technical support and maintenance services. You can consider buying new equipment if you are new to this business and need more technical know-how. New screen printing presses are accompanied by comprehensive customer support. It can help you get started and resolve any problems you may face while using them.

On the other hand, if you have an in-depth knowledge of how screen printing processes operate, you can give the used machine a chance. However, you must ensure that spare parts are easily available. And you have easy access to technical solutions and expertise for repairing and maintaining the equipment.

Wrapping Up

To decide whether you need to buy a new or used automatic screen printing machine, you must carefully consider multiple factors. While new machines offer performance, the latest features, and reliability, they also come with a price tag. On the other hand, used screen printing machines come with affordability and a plethora of options. But they also carry the risk of wear and tear, which might significantly limit their potential technological capabilities.

Therefore, to mitigate these risks, you need to do a thorough inspection of these machines. Buying from a reputable seller and going for refurbished printing presses can help you mitigate these risks too. Assessing your specific needs, priorities, and budget will ultimately play the biggest role in making a financially sound choice for your screen printing business.