Introduction:

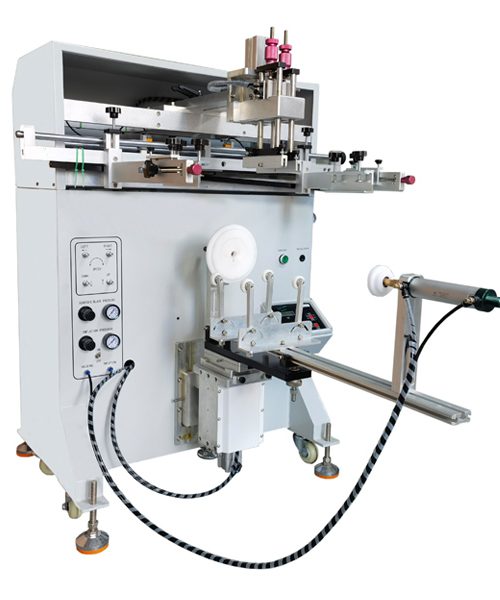

AP-400 semi-automatic bottle and container screen printer is a well designed and versatile machine.

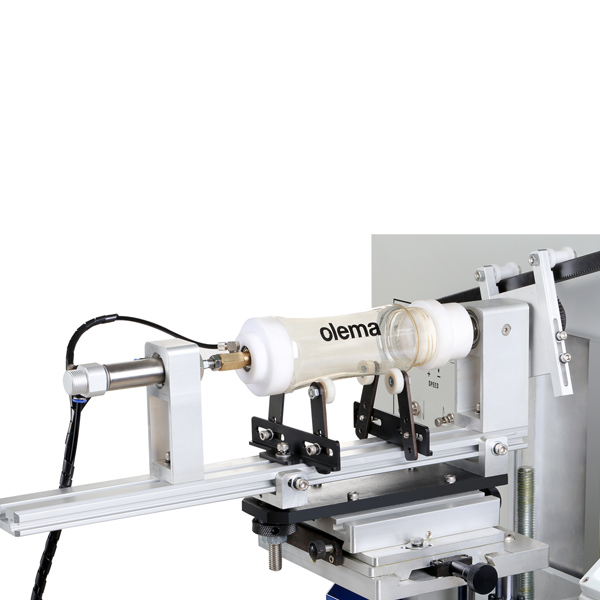

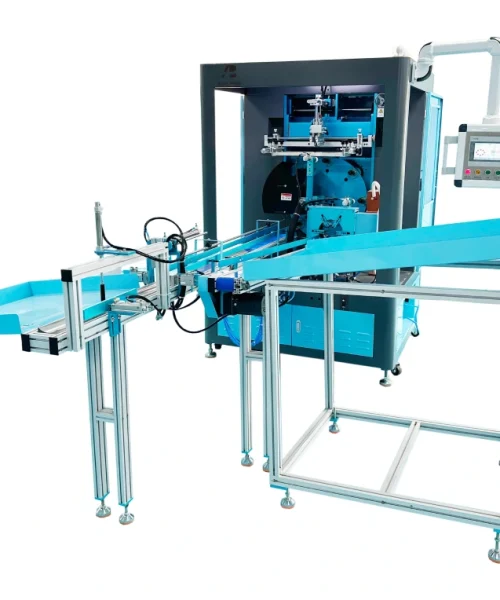

This AP-400 round screen printing machine can screen print on cylindrical objects such as blow molded bottles, cosmetic tubes, aluminum water bottles, drum sticks, glass pipettes, etc.

This type round screen printer features quick & simple tooling changeovers, precise mechanical registration & conveniently all controls are on the front panel, making the round screen printing machine the perfect all around universal screen printing press.

Features

Pneumatic controlled with shock absorber

Microprocessor controlled – PCB

Vertical part lift with height adjustment

Print stroke controlled with rodless cylinder or motor

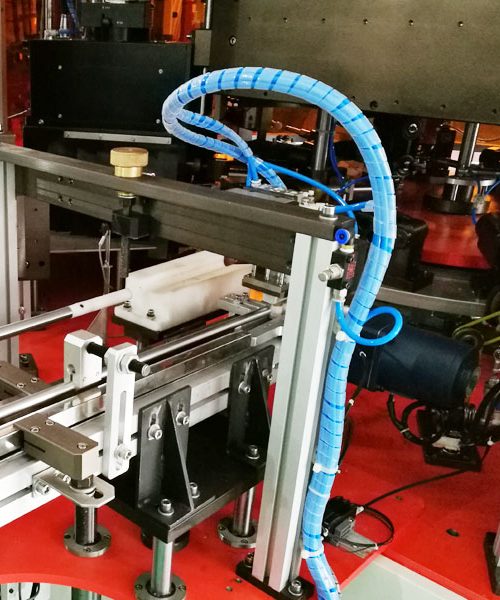

X/Y/R positioning ware-mounting table

Linear ball bearings on hardened shaft

Squeegee tilt, skew, height adjustable

Screen frame angle & tilt adjustable

Synchronized bottle inflation system with regulator

Regulated squeegee pressure with pressure gauge

Specifications

| Model Number: | AP-400 |

| Drive System: | Pneumatic |

| Frame Up/Down Stroke: | 100mm (3.94″) |

| Maximum Print Area Round: Maximum Print Area Oval: Maximum Print Area Flat: |

110mm (4.33″) Ø

340mm (13.39″) Arc Length 200 x 320mm (7.87″ x 12.60″) |

| Working Table Size: | 250 x 350mm (9.84″ x 13.78″) |

| Table Adjustment: | X,Y ± 15mm / θ 15 ° |

| Maximum Screen Frame Size: | 380 x 580mm (14.96″ x 22.83″) |

| Screen Frame Thickness: | 18 – 25mm (0.71″ -0.98″) |

| Squeegee Angle: | 0-15° |

| Printing Cycle Speed: | 1,200 cycles/hr |

| Squeegee Speed: | 20/min |

| Squeegee Pressure: | 2 – 4 Bar |

| Electric Source: | 110V/220V 50-60Hz 50W |

| Air Pressure Input: | 80 psi |

| Air Consumption: | 0.7 L/cycle |

| Machine Weight: | 150 kg (330.69 lbs) |

| Machine Weight (including crating): | 230 kg (507.06 lbs) |

| Dimensions (L x W x H): | 1,000 x 950 x 1,400mm |

| Crate Dimensions: | 1,080 x 1,010 x 1,520mm |

Reviews

There are no reviews yet.