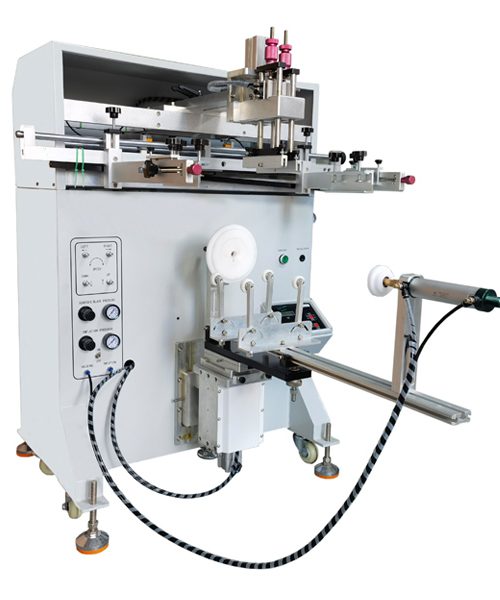

Product Overview of AP-600-8 Automatic Cup Printing Machine

The AP-600-8 Fully Automatic Vertical Rotary Screen Printing Machine is a highly efficient and precise printing device, specifically designed for cups, bottles, and other curved objects. It integrates a fully servo-driven high-speed system, LED curing system, and high-precision sensor positioning technology, offering a stable and fast printing experience. The machine supports both single-color and multi-color printing, making it versatile for a wide range of industries.

Application Industries and Scope

This machine is suitable for various materials and industries, including:

Its wide range of applications makes it an ideal solution for various curved surface printing needs.

Why Choose the AP-600-8 Vertical Rotary Screen Printing Machine?

The AP-600-8 offers unparalleled performance and versatility for curved surface printing, ensuring high productivity, precise quality, and cost efficiency. Whether you’re printing on plastic cups, glass bottles, or other curved containers, this machine delivers outstanding results.

Here’s what makes it stand out:

High-Speed Servo-Driven Rotary Table:

Equipped with 8 printing stations (optional 12 stations) to accommodate products of different sizes.

Accurate Sensor Positioning:

Photoelectric sensor ensures precise alignment and high-quality multi-color printing.

Fully Automated Production Design:

Includes material storage, automatic feeding, blowing for unloading, online stacking, and counting functions.

可以用一张图片展示机器的高速旋转工作台及多工位设计(例如8工位或12工位),同时体现光电传感器精准定位与自动上料、卸料的连贯操作。/展示旋转台和产品分布的动态画面,直观体现高速与精准定位。

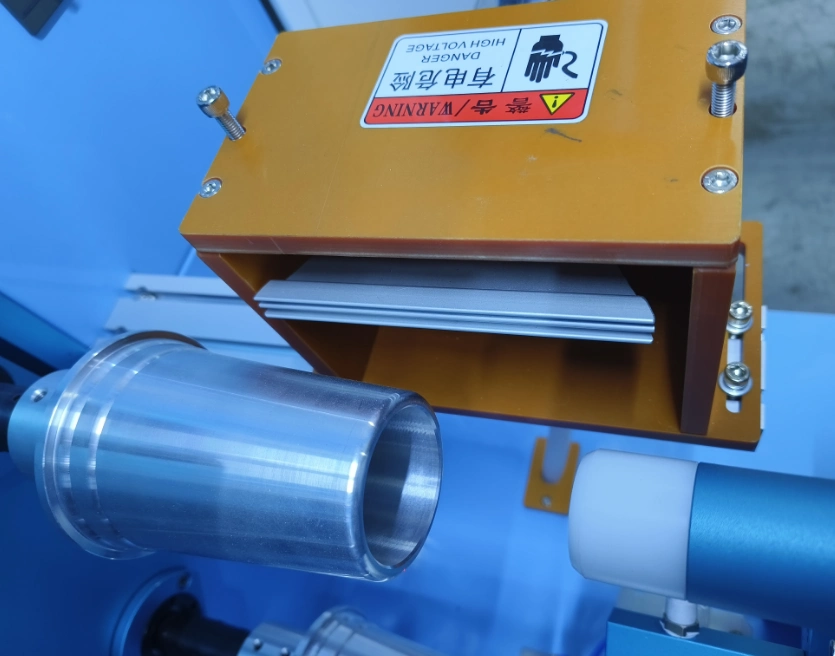

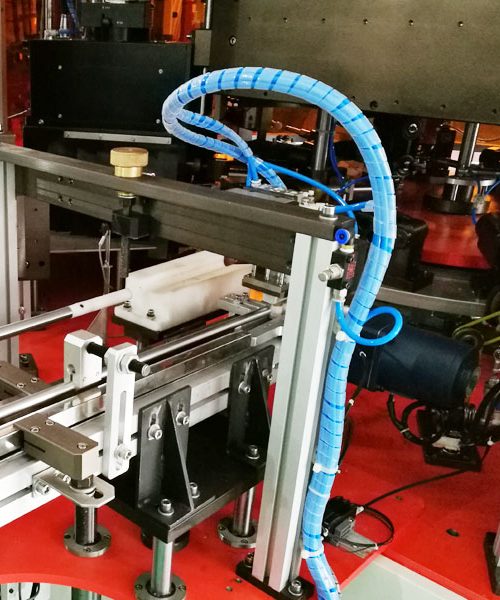

可以用一张图片展示印刷前的电晕处理和印后LED UV干固的流程,比如显示产品表面处理和瞬间干燥的实际效果。

Pre-Printing Surface Treatment:

Corona treatment enhances ink adhesion, suitable for materials like plastic and glass.

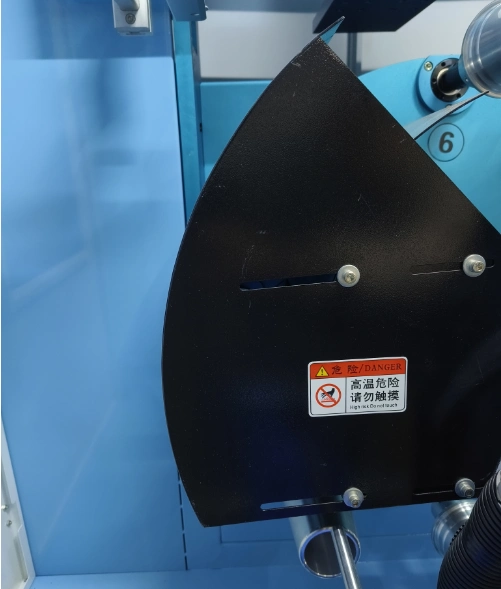

LED Curing System:

Efficient drying system for quick post-printing curing, improving production efficiency.

Visualized Touchscreen Control:

Intelligent touchscreen operation allows easy control and quick mode switching.

Cost-Effective and High-Efficiency:

Reduces labor costs and increases production speed, ideal for mass production.

Showcase of Printed Samples

The automatic cup printing machine adopts advanced printing technology, ensuring that every printed cup is clear and vibrant. It offers high production efficiency and easy operation, making it ideal for mass production needs. Its multifunctional design supports various cup types and sizes, greatly enhancing production flexibility and efficiency. Click on the images below to see more details of the finished prints and experience its excellent printing quality. If you would like to learn more about the product or customize your solution, please feel free to contact us. We are committed to providing professional consultation and services.

Technical Details of Automatic Cup Printing Machine

| Model No. | AP-600-8 |

|---|---|

| Printing speed | Single color 3600-4800 pcs/hour Two color 1800-2400 pcs/hour |

| Screen frame size | 180x450mm |

| Max. printing diameter | 110mm |

| Rotarytable drive | Servo motor |

| Photoelectric sensor | Keyence or Leuze |

| Pre-treatment Curing system | Corona LED UV curing system |

| Electrical supply | AC220V 50/60Hz 7KW |

| Air requirement | 0.4-0.7Mpa |

| Machine Dimensions: | L3500 x W2500 x H1950mm |

| Net Weight: | 950KG |

Specifications are subject to change without prior notification.

Key Components and Visual Details

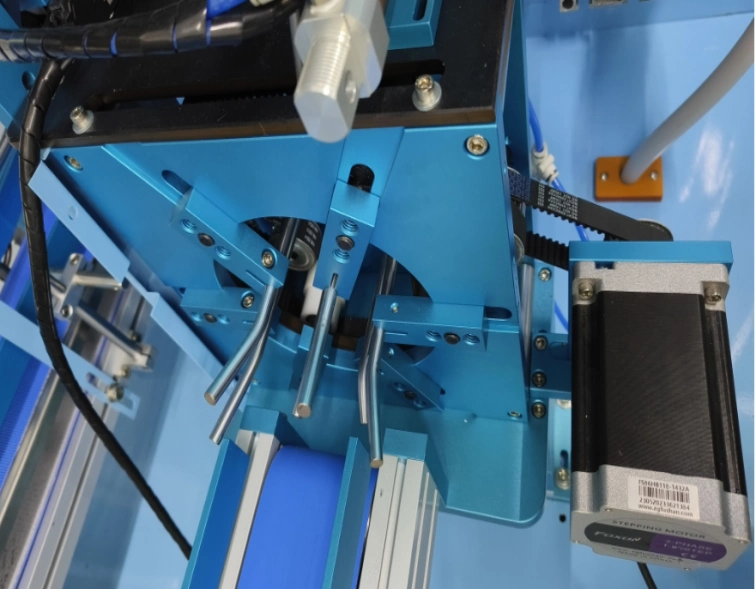

Movable Console

Two Types of Feeding Structures

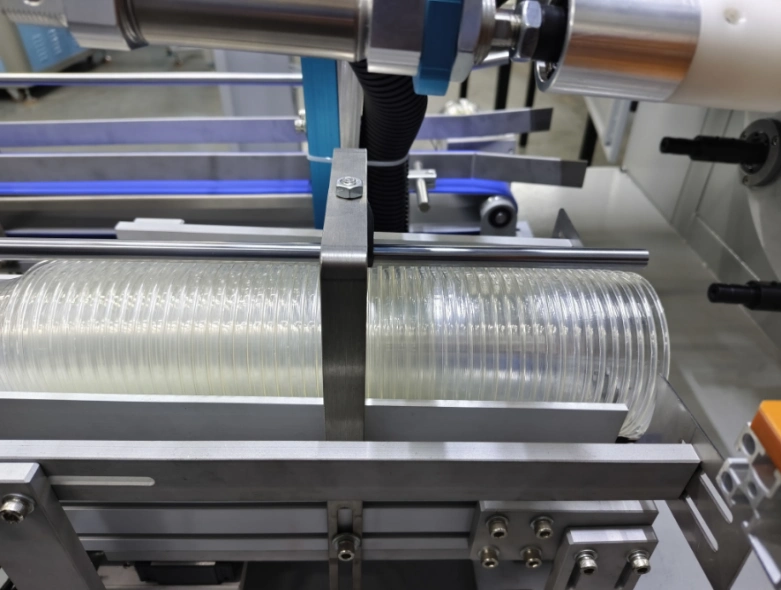

Spiral Distribution Structure

Push Feeding Structure

Corona Treating

Screen Printing Station

LED UV Curing System

Loading And Unloading Storage Area

Stacking And Counting Area

Contact Us

Ready to upgrade your printing capabilities with the Servo Rotary Table Series? Get in touch with us today for more details!

With the Servo Rotary Table Series, you’ll discover the perfect blend of precision, efficiency, and versatility. Whether you need a glass bottle printing machine or a comprehensive solution for other container types, this system delivers consistent, professional results to elevate your products.

Reviews

There are no reviews yet.