Product Overview

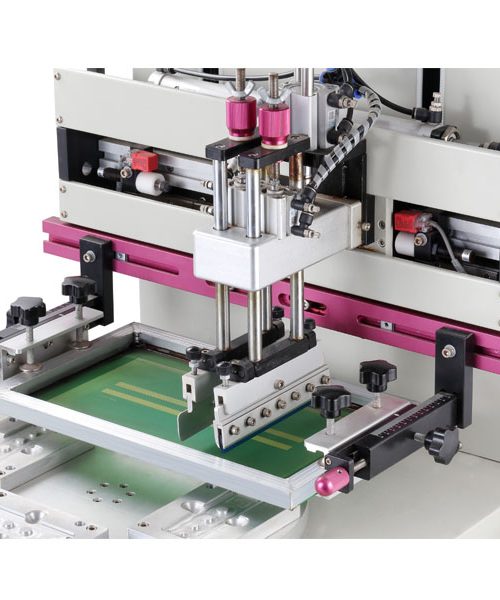

The AP-120200 is a high-precision flatbed screen printing machine designed for flat films, sheets, and thin-plate substrates. With advanced servo-driven technology and a robust four-column sliding table structure, it ensures exceptional accuracy and efficiency for large-scale printing applications.

Features:

1. Screen Frame Structure:

- Planetary reducer plus chain driven four-column synchronous transmission with servo precision positioning.

- Equipped with four-column locking devices to ensure parallelism between printing stroke and the working table. Left/right frame arms include height adjustment mechanisms for leveling the screen.

- Screen frame extends backward for easy centering during printing.

- Micro-adjustment/screen/frame arm pneumatic locking for quick screen installation and removal. Includes check valves to maintain locking even during power or air supply failure.

- The servo motor synchronously lifts the screen to prevent the screen from sticking to the printing surface. The lifting height and starting point are set by numerical control, and the automatic calculation is synchronized with the printing speed (the lifting is completed just after printing)

2. Table Structure

- Servo motor + swing arm drive for front/rear table movement. Linear guide rails ensure positioning accuracy ≤0.05 mm.

- High-rigidity aluminum profiles for rail support and maintenance. Precision-machined mounting surfaces ensure parallel alignment.

- Precision-processed aluminum alloy table with high strength and flatness.

- φ1.0 mm dense vacuum holes ensure substrate adhesion and prevent ink unevenness caused by vacuum depressions.

3. Printing Structure

- Servo-driven printing stroke with linear guide rails. Printing/flooding speeds are digital controlled for stable motion and precise positioning.

- The squeegee/flood bar up and down movement is driven by pneumatic cylinders on the guide rails, ensuring accurate and smooth guidance, with the printing pressure fully reflected on the printed material, guaranteeing uniform thickness of the printing film.

- Equipped with a depth/angle/tilt adjustment mechanism for the squeegee/flood bar (depth fine-tuning is achieved with a precision micrometer).

- The shifting printing feature allows a lightly printing at the initial segment of the stroke (set by numerical control) before transitioning to the set printing pressure, enabling the squeegee to avoid the edges of the printed material, preventing damage to the screen mesh and squeegee, and facilitating ink collection with the light printing.

4. Control System:

7-inch HMI for parameter settings and data storage, achieving digital control of printing quality.

5. Safety Features:

- The air filter pressure regulator is equipped with an automatic pressure detection switch. If the air source pressure is insufficient, the machine will automatically stop and issue a warning, ensuring that all printing is completed under sufficient air pressure.

- A front safety bar prevents the table from moving out when not in position, protecting the operator’s safety.

- The safety protection circuit will immediately stop the machine and display the fault on the HMI in case of any setting or operational errors or malfunctions. It is equipped with a safety reset button.

Main Parameters:

| Maximum Printing Area | 1200*2000 mm |

| Workable Area | 1400*2450 mm |

| Max Screen Frame Size | 1700*2700 mm |

| Table Accuracy | ±0.15 mm |

| Reprint Accuracy | ≤0.05 mm |

| Substrate Thickness | ≤20 mm |

| Max Printing Speed | 150 cycles/hour |

| Printing Pressure | 0.4-0.6 kgf/cm² |

| Worktable Drive | Germany SEW motor |

| Control System | Mitsubishi PLC + touch screen |

| Electricity Requirements | 380V-480V 3Phase 50/60Hz |

| Machine Weight | 2000 kg |

| Dimensions | 3700x3550x1600 mm |

Reviews

There are no reviews yet.