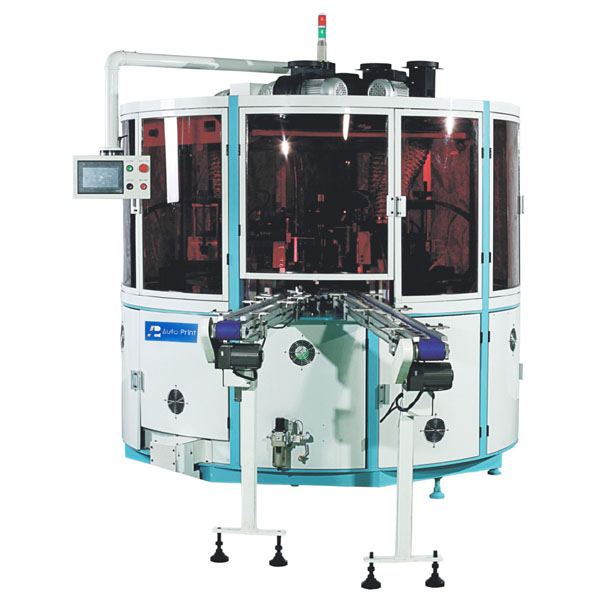

The AP-F324 is a fully automatic UV screen printing machine designed for flat surfaces that offers increased productivity and unrivalled value, available print dressing cases, stationery rulers, flat pens, etc.

The AP-F324 is driven by a SANKYO rotary positioning drive system and features a SITI main drive motor with a barrel cam.

The UV screen printing inks are automatically cured with high powered UV lamps positioned after each printing station. After loading of the flat objects there is a pre-flame treating station and de-ionizing / cleaning station (optional) to ensure quality printing results with fewer defects.

The AP-F324 system is equipped with HANOVIA brand (US made) UV curing units which are outfitted with high intensity mercury UV bulbs.

3 Color Automatic Flat Screen Printing Machine Features:

- High precision mechanical rotary indexer (24 stations)

- OMRON PLC controlled with touch screen

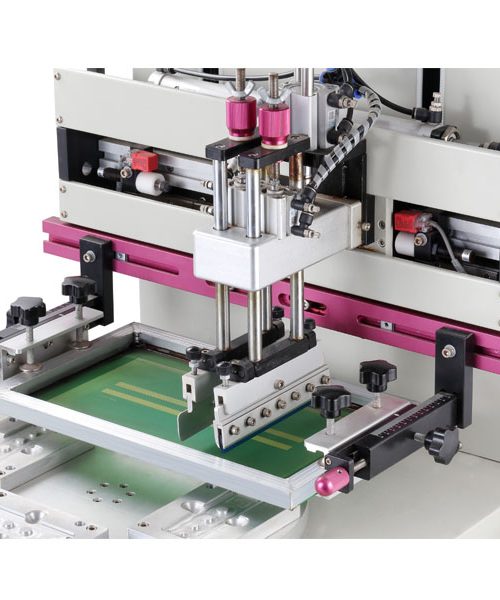

- Mechanically synchronized print heads for precise printing results

- Automatic loading and unloading system

- Quick and easy set-up and change-overs

- Motor controlled optical pre-registration device

- Adjustable squeegee angle and height

- Up to 110 x 90mm (4.33” x 3.54”) print area

- HANOVIA brand UV Curing units (US Made)

- Equipped with interlocking safety doors

- Printing speeds up to 45ppm

3 Color Automatic Flat Screen Printing Machine Specifications

| Model NO.: | AP-F324 |

| Print product size: | L160 x W160 x H100 mm |

| Max. print area: | L110 x W90 mm |

| Max. printing speed: | 45 pcs/min |

| Drive: | Mechanical driven |

| Flame treating system: | 1 unit |

| Print head: | 3 units |

| Stations: | 24 stations |

| UV system: | 3 units electronic UV system, 5KW per each |

| Deionizing device: | 1 unit |

| Motor: | ITALY SITI |

| Control system: | OMRON PLC & Touch Screen |

| Pneumatic parts: | Japan SMC |

| Electrical supply: | 380V/480V 3phase 50Hz/60Hz |

| Air requirement: | 6-8bar |

| Power consumption: | 10 KW |

| Machine dimension: | L4950 x W3150 x H2350 mm |

| Weight: | 1500 KG |

Reviews

There are no reviews yet.