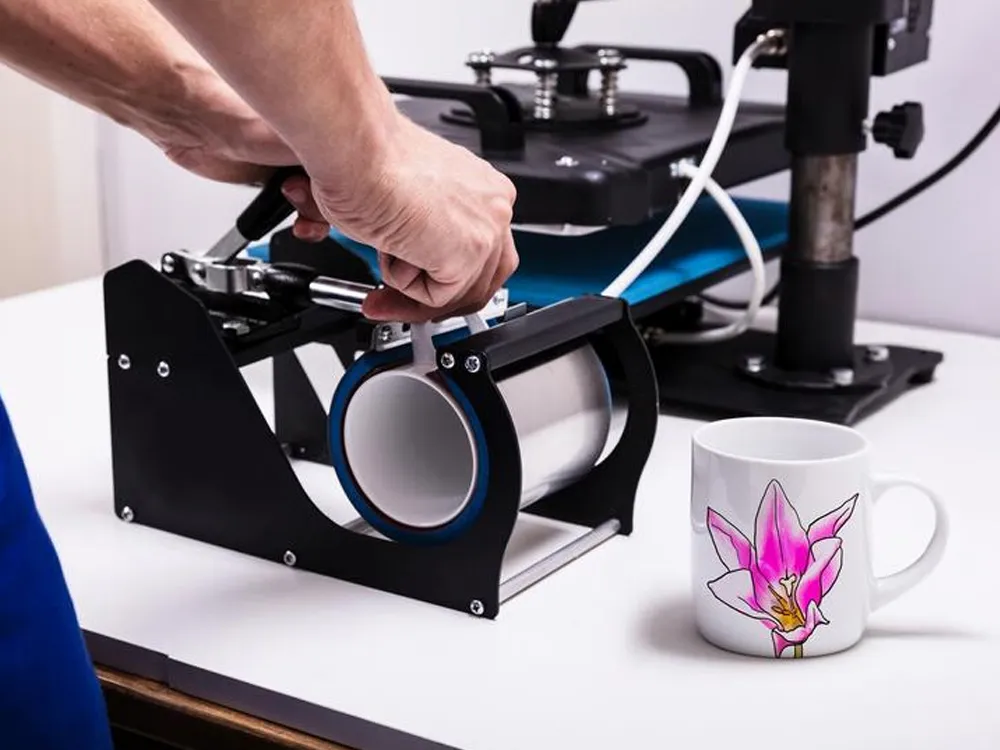

Are you new to the mug printing business and trying to choose the best mug screen printing machine to enhance your product? Or are you a designer looking to take your work of art to the next level? You’ve landed on the right page.

Mug printing is one of the important ways printing companies and freelance designers market their brand, alongside printing on caps, T-shirts, and stationeries. Mug printing is one of the most attractive mediums to showcase your skills as a designer.

Choosing the right one can take time and effort. After researching and testing many products, I found the best mug screen printing machines. This piece provides tips on what to consider when choosing a mug screen printing machine.

Tips to Choose the Best Mug Screen Printing Machine (Production Consideration)

Choosing an excellent screen-printing machine for mugs depends on these essential features: Price of the machine, Ink type, appearance, and functionality.

Price of the Machine

Price influences every product, which in turn influences/determines our purchasing power. When the machine’s price exceeds the available capital, you may not buy it. So, researching the price range of machines to your purchasing power is highly recommended.

Functionality

Talking about functionality, the most crucial factor needed to select a good mug printing machine is gear-driven rather than friction driven. The gear needs to match the diameter of the mug to be printed on so that it covers the mug and easily synchronizes with the mug screen. The machine/tool will also need a mug-holding handle that can be used effectively for multi-colored printing.

Another vital factor to consider is the handle of the mug hitting the screen for the print cycle. The image is expected to cover the mug/cup surface as much as possible. However, the screen will be an obstruction unless appropriately made. Thus, the screen should take an H shape with the mesh in the middle, which enables the handles to extend at an angle of 45 degrees upward.

Material Property

The type of material to be printed on is one of the crucial factors to consider when choosing the type of mug screen printing machine to be used. The material the mug is made of will influence the type of mug screen printing machine you choose. For example, plastic and glass mugs are naturally smooth, nonporous materials. They can be challenging to print on when printing because of their material. Ink adhesion problems can be encountered if the correct type of machines and materials are not used.

Cups made of plastic or glass are non-porous. Such materials are usually pretreated using a procedure known as a flame treatment. This improves their ink adhesion. But exposing mugs made of plastic and glass through a flame processor only changes the material’s molecular structure. No visual appearance will be changed in any way. Mugs made of ceramic can also be processed with the correct pretreatment equipment designed for ceramic. Then transfer to screen printing machine.

Ink Type

Using a pre-treatment flame treatment system is one of the ways to improve the ink adhesion of the material. Ink type and how much the printing ink lasts are also vital factors. There are different types, such as UV ink, plastisol, etc. UV curing is used in many processes to strengthen and improve the durability of many polymers, varnishes, and inks. It is highly beneficial in speeding up product cycle times.

Incorporating UV curing with a suitable mug screen printing machine can be as seamless as pretreating. This can significantly increase efficiency, profitability, and product durability.

Tips to Choose the Best Mug Screen Printing Machine (General Consideration)

Choosing an excellent screen-printing machine for mugs depends on these essential features: Price of the machine, Ink type, appearance, and functionality.

Durability and Reliability

Durability is a “measure of product life,” according to the Harvard school of business. In other words, it is how long the mug printing machine performs its duties before its performance degrades. In contrast, reliability is essentially the opposite of failure. That is the ability of a machine to work without any disturbance when used during its service life.

Both the durability and reliability of the machine are significant factors to consider before purchasing any machine.

Machine’s Versatility

The first thing to consider when buying a mug screen printing machine is its versatility. That is the ability of the machine to process different materials. Switching between different materials and sizes is critical, whether ceramic, plastic, or glass. It is highly recommended you get a machine that can print comfortably on these materials.

Level of Automation Needed

The level of automation required to achieve your production goals is another essential factor to consider when choosing the best mug screen-printing machine. You need to consider whether you need large-scale production or small-scale production. Go for a machine with specifications that can handle the level of production you are making.

Pre-treatment and Post-treatment Capability

It is necessary to consider a machine capable of pre-treatment and post-treatment capability. But most automatic screen-printing machines are incorporated with both pretreating and UV curing systems. They can improve the quality and profitability of products. You might need a printing machine with a flame treatment system and a UV curing system for post-treatment.

Production Volume

The volume of your print job is also essential. Because screen printing is proven cost-effective, especially in high-volume printing processes. Getting the best screen printing machine will enhance your art and business if you are into large productions. It allows you to effectively print your custom designs on the mugs/ coffee cups for your customers.

I recommend the ONCE mug screen printing machine. Below we discuss its features and benefits.

ONCE Mug Screen Printing Machine

Looking for a cost-effective screen printing machine for mugs, considering the above factors, ONCE is the machine manufacturer we recommend. The following two machines are among their most popular. If you need it, you can continue to learn more.

3 Color Automatic Round Mug Silk Screen Printing Machine

This 3-color automatic mug silk screen printing machine is an incredible design printing equipment. It is commonly used in the food and beverage, pharmaceuticals, and personal care industries. Its ability to produce high-quality, multi-colored prints quickly and efficiently. So it becomes the best option for business owners looking to enhance the branding of their products.

The machine runs independently, reducing the need for manual labor while increasing efficiency. It has three independent color stations, allowing it to print designs in up to three colors in a single phase. The color stations have ink reservoirs, silk screens with the desired designs, and a drying station. Also, the 3-color mug silk printing machine consists of a conveyor system that transports bottles during the printing process. The auto-adjustable settings for controlling the speed, pressure, and ink flow ensure consistent and high-quality prints.

Advantages of the 3-color Mug Silk Screen Printing Machine:

The advantages of using a 3-color automatic round bottle silk screen printing machine include:

- Increased Efficiency

It uses automatic processes and multiple color stations. The machine can produce more printed bottles in less time than manual printing.

- Improved Consistency

Human error is reduced in the machine, bringing about consistency in the quality and placement of the printed designs.

- Enhanced Color Capabilities

Because the machine can print in up to three colors, more intricate and vibrant designs can be created easily.

- Reduced Cost of Labor

The automation feature reduces the need for manual labor, thus reducing the cost of labor.

- Versatility

This machine can print on various bottles of different materials, sizes, and shapes.

The 3-color mug silk screen printing machine offers greater efficiency, consistency, and versatility, making it an alluring choice for different users, especially large printing industries.

Multicolor Semi-Automatic Screen Printing Machine for Mugs

Unlike a fully automated machine, the multicolor semi-automatic machine requires manual intervention to some extent. However, automation still offers many benefits. Including increased efficiency and consistency in printing.

The semi-automatic machine is mainly suited for small business owners producing smaller quantities. Also suitable for those who wish to incorporate manual adjustments into their printing process.

The multicolor semi-automatic mug screen printing machine consists of a conveyor system, multiple color stations equipped with ink reservoirs, silk screens with the desired designs, and a drying station for the ink to set. In contrast to a fully automatic machine, a semi-automatic machine may require manual bottle loading and unloading. And it also needs manual adjustments of the ink flow and pressure.

Advantages of a Multicolor Semi-automatic Screen Printing Machine for Mugs

There are several advantages of using a multicolor semi-automatic mug screen printing machine. These include:

- Increased Efficiency

The machine’s semi-automatic nature increases efficiency over manual printing methods. It also retains some manual control of the printing system.

- Improved Consistency

Although it’s not fully automatic, the semi-automatic system still reduces the possibility of human error. It can enhance the printed designs’ quality and placement.

- Enhanced Color Capabilities

The machine’s ability to print with multiple colors allows for creating more intricate and vibrant designs.

- Cost-Effective

It produces a cost-effective solution for small-scale businesses that produce smaller quantities of printed bottles. Including those who want to be able to make manual adjustments to their printing process.

- Versatility

The semi-automatic machine is capable of printing on a variety of different bottle materials, sizes, and shapes.

Final Thought

The multicolor semi-automatic screen printing machine provides a good balance of increased efficiency and manual control. It is a good choice for businesses of various sizes and production.

In conclusion, evaluating every one of the considerations listed above with a specialist is definitely worth your time. They can offer assistance in evaluating your specific screen printing needs. So can choose the best mug screen printing machine which provides the most benefit to your application.