Introduction

In the past, the screen printing process was all printed by hand. With the development of the era of automation, the screen printing process has become more and more automated. The fully automatic screen printing machine is named according to the degree of automation of the screen printing machine. Auto screen printing machine is a development trend of screen printing machine after manual screen printing machine and semi-automatic screen printing machine. It uses more advanced technology and technology to make the screen printing process more accurate, faster, and more automated.

What is automatic screen printing machine

First understand the four major printing methods, namely lithographic printing, embossing, gravure, and stencil printing, while stencil printing includes transcription, hollow pattern, spray, and screen printing. Therefore, an automatic screen printer is a machine for screen printing. Automatic screen printer is a machine that prints text and images. It is a general term for machines used to produce printed matter.

Working principle of automatic screen printing machine

The automatic screen printer uses the basic principle that the graphic part of the screen printing plate is ink-permeable and the non-graphic part is not ink-permeable for printing. The auto screen printing machine pours ink on one end of the screen printing plate and uses a squeegee to apply a certain pressure on the ink position on the screen printing plate while moving toward the other end of the screen printing plate. The ink is squeezed from the mesh of the graphic part to the substrate by the squeegee while it is moving. Due to the viscosity of the ink, the imprint is fixed within a certain range. During the printing process, the squeegee is always in line contact with the screen printing plate and the substrate, and the contact line moves with the movement of the squeegee. The screen printing plate is in mobile line contact with the substrate, while the other parts of the screen printing plate are in a disengaged state from the substrate. The ink and the screen are broken to ensure the printing dimensional accuracy and avoid smearing the substrate. When the squeegee is scraped across the entire layout, it is lifted, and the screen printing plate is lifted at the same time, and the ink is gently scraped back to the original position. So far is a printing process of the automatic screen printing machine.

Features of automatic screen printing machine

- First of all, the automatic screen printer has its own unique frequency conversion speed regulation device, the printing speed can be adjusted, from 20 to 70 times per minute auto screen printing machine.

- Secondly, the auto screen printing machine has its own electronic counter, which can automatically shut down according to the pre-designed total number, saving a lot of manpower and financial resources.

- Third, the automatic screen printer is very accurate in point and color, because it is equipped with a multi-color printing electric eye device, which can improve the quality of printing.

- Fourth, large-area background color, outline dots, and fine-character patterns are suitable for screen printing machines, because the high quality of the automatic screen printer not only makes the patterns clear, the colors are bright, and it is not easy to fade.

- Fifth, the reason why the pattern printed by the auto screen printing machine is bright and clear is that the ink adhesion of the screen printing machine is very good, and the ink layer is relatively thick, so the pattern is not easy to fade.

- Sixth, the fully automatic screen printing machine can not only be used alone, but also can be connected to a UV dryer, or a slitting machine, a reminder, and other auxiliary machines.

- Seventh, because of the high-quality configuration of the automatic screen printing machine, there are also a lot of savings in consumables.

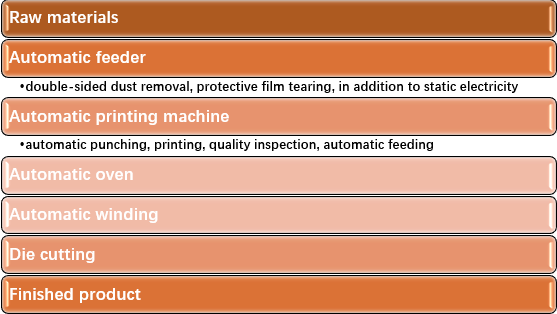

The process of automatic screen printing machine

The scope of application of automatic screen printing machine

plastic cosmetic Packing box Metal plate Scale plate Acrylic Plexiglass electronic product household items sticker Leather transfer paper Various types of cups, barrels, glass, baseball bats, wooden boards

Types of automatic screen printing machine

Automatic cylindrical screen printing machine

- A screen printer with a cylindrical screen. Inside the cylinder, there is an ink pipe with nozzles and a doctor blade with an empty sleeve on the shaft. When an automatic cylindrical screen printing machine is working, the cylinder plate makes continuous rotation movement, and the ink knife does not move. Cylindrical printing machines can be divided into garden net platform types and rotary net drums.

Automatic flat screen printing machine

- The screen is a flat screen printing machine. It is a reciprocating intermittent movement, which limits the printing speed. It can be divided into open book type, horizontal lift type, mobile type, printing table tilt and horizontal sliding type, printing table fan-shaped opening and closing type, printing table rotating type, roller type, etc.

Automatic curved screen printing machine

- Curved screen printing machines are classified according to the degree of automation, including semi-automatic curved screen printing machines and automatic curved screen printing; according to the shape of the screen printing plate, there are flat screen curved screen printing machines and rotary screen curved screen printing machines.

Common automatic screen printing machine

plastic cup printing machine

- The plastic cup printing machine can print simple patterns or patterns with transitional colors at one time. The plastic cup printing machine is capable of large-area irregular printing on thick and thin materials. The color of the product printed with the plastic cup printing machine is clear, will not fade for a long time, and the texture of the picture is very strong.

bottle screen printing machine

- All kinds of bottles are common in life. Bottle screen printing machine is widely used in catering, medicine, chemical, and other industries. Therefore, today’s demand for bottle printing is also great, and the demand for bottle printer machines has also increased.

screen printing machine for glass bottles

- Like ordinary bottles, glass bottles are also widely used in various industries. No matter what glass container you want to print, the high-performance screen printing machine for glass bottles can solve it.

printing machine for disposable cups

- Disposable cups are commonly used daily and work supplies. More and more companies are customizing logos on disposable cups. Therefore, the demand for printing machine for disposable cups is increasing.

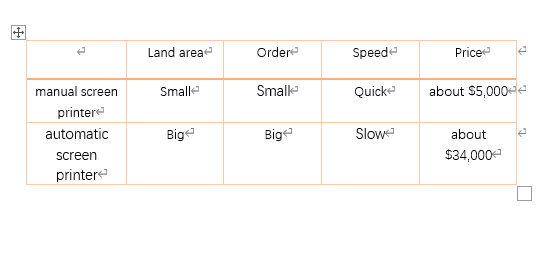

The difference between a manual screen printing machine and an automatic screen printing machine

Common faults and solutions in the printing process

Fault 1: The work surface of the automatic screen printing machine does not inhale.

Reason: The control solenoid valve is broken or the internal block is damaged.

Solution: Replace and repair.

Fault 2: The vertical slide of the automatic screen printer rises slowly.

Reason: The bearing of the vertical sliding seat is oil-free or the piston of the cylinder is worn out, and the shaft is bent by the magnetic impact.

Solution: Replenish the oil, change the piston password, and adjust the axis.

Fault 3: Step on the foot switch and the vertical sliding seat will descend when it is working semi-automatically, and the printing seat will not move after it moves to the left.

Reason: The proximity switch on the left side of the sliding seat is not sensed or there is a problem.

Solution: Adjust the sensing point of the left proximity switch or replace the proximity switch.

Fault 4: Stepping on the foot switch during semi-automatic operation, the sliding seat descends and moves to the left and then rises but does not move to the right.

Reason: The proximity switch on the upper left side of the vertical sliding seat is not sensed or the proximity switch has a problem.

Solution: Adjust the upper proximity switch sensor or a better proximity switch.

Fault 5: After the automatic screen printing machine is switched, the rising motion is half a beat slowly.

Reason: The control solenoid valve is blocked by foreign matter or the solenoid valve is faulty.

Solution: Remove the solenoid valve to clean or replace the solenoid valve.

Fault 6: Automatically cannot start.

Reason: The micro switches of the upper and lower cylinders of the automatic screen printing machine are normally closed, and the contacts cannot be turned on or the timer is damaged.

Solution: Repair the micro switch or replace the timer.

Summary

With the widespread application of automation, the development momentum of automatic screen printing machine is getting better and better, and more automatic screen printers are invested in this field. The market share of auto screen printing machine is rapidly increasing, and many large companies have already put it into use, and some small and medium-sized enterprises are also gradually introducing them. The fully automatic screen printing machine will inevitably replace manual and semi-automatic screen printing machines in the future, which is an inevitable trend in the development of the industry.