Well, welcome to a specific topic about the cylindrical screen printing machine. Although the screen printing cylinder press can print circular containers, it does not mean that only circular containers can be printed. The cylindrical printing press is suitable for all kinds of regular curved objects, such as cylindrical bottles, frustum-shaped objects, or the arc surface of some irregular objects that can be printed.

The cylindrical screen printing machine is a kind of equipment in the printing industry, which has been widely used in our life and work. Do you want to buy a cylindrical printing press? We have listed 10 of the most popular screen printing cylinder presses for you. So this will be a good start for you to buy a cylindrical screen printing machine.

What is The Best Cylindrical Screen Printing Machine

For this question, I think the one that suits me is the best.

If you have a limited budget and are not familiar with screen printing cylinder press, you can consider purchasing a manual cylindrical screen printing machine. This simple, effective cylindrical printing press is easy to get started with.

If money is not an obstacle for you, then the expensive automatic cylindrical screen printing machine is sure to impress you. It provides not only a solid structural system but also efficiency and operational stability.

Top1: 1 Color Automatic UV Silk Screen Bottle Printing Machine

This is a 1 color automatic cylindrical screen printing machine. It is manufactured by a famous screen printing machine manufacturer. With a wealth of experience and professional knowledge, ONCE has now become a leader in the industry, and it is the ideal manufacturer for you to buy a cylindrical printing press.

You can use this automatic cylindrical screen printing machine to print on any round and oval container. And it prints fast, perfect for large jobs. As you can see, the size and footprint of this machine are relatively large, so it is suitable for a spacious factory, not for home use.

Reasons Why This Cylindrical Screen Printing Machine is So Popular:

- Fast speed, can print 4200 bottles per hour.

- High running stability and accurate color registration.

- Can be printed on any round, square, or oval bottle.

- Touch screen control.

- With a smart UV system, it can save energy consumption.

- Anti-static dust removal and flame treatment on the bottle surface.

Specifications of This Cylindrical Screen Printing Machine

| Model NO.: | OS-767-1C |

| Round container size: | Diameter: φ10-100mm, Height: 30-260mm |

| Round container max. print area: | L 260 x W220mm |

| Oval container size: | R: 10-250mm, Height: 30-260mm |

| Oval container max. print area: | L 120 x W220mm |

| Drive: | Mechanical Driven |

| Control system: | OMRON PLC & Touch Screen |

| Max. printing capacity: | 70 pcs/min |

| Registration tolerance: | +/- 0.2 mm |

| Infeed conveyor: | 1 unit, length: 2 meters |

| Deionizing device: | 1 unit |

| Flame treating system: | 1 unit, LP gas |

| Motor: | ITALY MOTOVARIO |

| Print head: | 1 unit |

| UV system: | 1 unit intelligent UV system, 5KW per each |

| Outfeed conveyor: | 1 unit, Length: 2 meters |

| Frequency Converter: | OMRON |

| Pneumatic parts: | FESTO or SMC |

| Electrical: | 380V 3phase 50Hz |

| Air requirement: | 5-7 bar |

| Air consumption: | 85 liter/ minute max. (per color) |

| Power consumption: | 5.4 KW/color x 1 |

| Machine size(LxWxH): | Main machine: 2300x1800x1700mm |

| Weight: | 1600 KG |

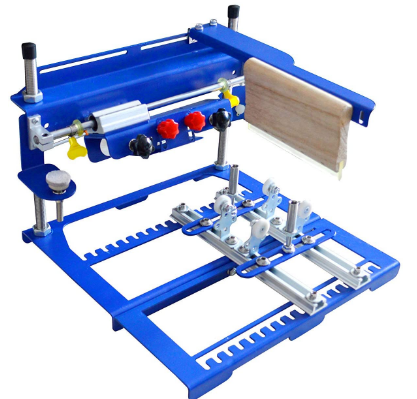

Top2: TECHTONGDA 6×8 Inches Cylindrical Screen Printing Machine

This cylindrical silk screen printing machine can be used to print flat cylindrical or conical shaped items, such as bottles, cups, pens, etc. The operator can adjust the orientation of the screen according to printing needs. Even lefties can use it. In addition, the screen height can also be adjusted. Screen clips hold the screen in both directions, so it stays strong and stable throughout the printing process.

This cylindrical printing press can be repeated with the same printing effect. Because the two pillars that come with it can keep the print still while printing. And importantly, the small size of this machine makes it ideal for home and novice use as well.

Reasons Why This Cylindrical Screen Printing Machine Sells Well:

- The printing operation process is very smooth.

- The screen height is adjustable.

- Allows repeated printing with the same printing effect.

Specifications of This Cylindrical Screen Printing Machine

| ASIN | B082FX7TM6 |

| Item Weight | 17.26 pounds (7.77 kg) |

| Color | Blue |

| Size | 6×8 Inches (172.7 cm) |

| Maximum Frame Thickness | 1.4″ |

| Printing Diameter | below 6.7″ |

| Maximum Height | 7.8″ |

| Brand | TECHTONGDA |

| Material | Steel plate |

| Number of Items | 1 |

Top3: Manual Cylinder Screen Printing Machine

This is a manual cylindrical screen printing machine with a simple structure and convenient operation. As you can see, its appearance is quite simple. It is suitable for monochromatic printing on cylindrical surfaces, such as bottles, cups, pens, etc.

This simple manual cylindrical printing press adjusts the working width to suit the diameter of different objects. In addition, Awesome Sellers is also a professional and trustworthy machine manufacturer.

Reasons Why This Manual Cylindrical Screen Printing Machine Sells Well:

- Manual screen printing cylinder press.

- Simple structure and convenient operation.

- Adjustable working width to adapt to the diameter of different objects.

- It is suitable for single-color printing on the surface of cylindrical objects.

Specifications of This Cylindrical Screen Printing Machine

| Product Color | blue |

| Pallet Size | 400x 500mm |

| Machine using material | steel plate |

| Machine surface treatment | Electrostatic spraying |

| Pallet Materials : | HDF (High Density Fiberboard) |

| Net weight | 25KG |

| Gross weight | 26KG |

| Packing size | 60*42*43cm |

| Packing volume | 0.11m³ |

| Packing material | Export carton |

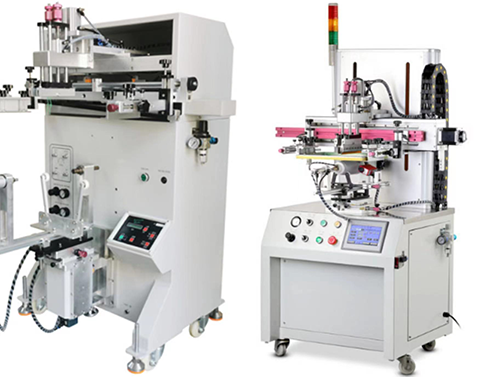

Top4: Automatic Cylindrical Screen Printing Machine

Wenzhou Changs Machinery Co., Ltd is a professional manufacturer of cylindrical silk screen printing machines. With sufficient technical support and 16 years of manufacturing experience, it has won wide acclaim in the industry.

This is an automatic cylindrical printing press with two types. It is highly automated, easy and simple to operate, and requires little manpower. It can print on flat, curved, and round objects. The automatic oil scraping and oil return function of this machine can ensure the stability of the printing process. In order to meet different printing requirements and take into account the operator’s proficiency, the printing speed is adjustable. So this is also a humanized design machine.

Reasons Why This Manual Cylindrical Screen Printing Machine is So Popular:

- With a high degree of automation, the microcomputer controls all functions.

- The worktable can be lifted up and down, and can be fine-tuned up and down, and the printing accuracy is high.

- Automated balancing oil knife to maintain the equilibrium of printing pressure.

- Place a 5-digit counter in the center.

- It has the printing functions of a circle, plane, and curved surface.

Specifications of This Cylindrical Screen Printing Machine

| Type | SPC300 | SPC450 |

| Maximum frame size | 480X280mm | 630X380mm |

| Maximum printing speed | 1000pcs/hr | 1000pcs/hr |

| Maximum printing area | 150X260mm | 200X420mm |

| Maximum printing height | 100mm | 240mm |

| Gas consumption | 60L/min(6bar) | 85L/min(6bar) |

| Installation dimensions | 1020X820X1420mm | 1100X980X1520mm |

| Heavy volume | 140Kg | 215Kg |

| Type | SPC700 | SPC1000 |

| Maximum frame size | 880X380mm | 1180X380mm |

| Maximum printing speed | 700pcs/hr | 500pcs/hr |

| Maximum printing area | 660X210mm | 950X300mm |

| Maximum printing height | 320mm | 380mm |

| Gas consumption | 80L/min(6bar) | 90L/min(6bar) |

| Installation dimensions | 973X1292X4620mm | 973X1592X1720mm |

| Heavy volume | 430Kg | 530Kg |

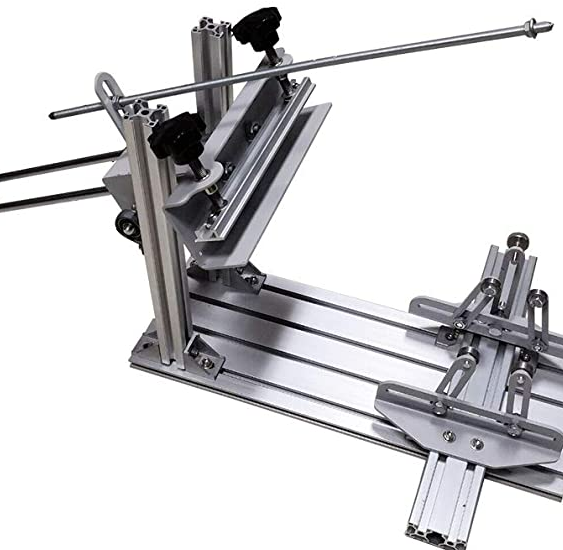

Top5: Manual Cylindrical Silk Screen Printing Machine

This is a newly designed simple and practical manual cylindrical printing press. As you can see, its exterior is all aluminum, which is also a feature that differentiates it from older models. This design is not only beautiful but also lightweight. It adopts a dual guide rail design, which can achieve smooth and low noise. You can use this cylindrical silk screen printing machine to print mugs, pens, etc.

A handy little cylindrical printing press can save you a lot of trouble. It is very easy to install and remove. In addition, the scraper bar adjustment device can realize the free adjustment of scraper height. Inexpensive, this machine is the best choice for personal homes and small businesses.

Reasons Why This Manual Cylindrical Screen Printing Machine is So Popular:

- This machine is manually operated, suitable for home and small business.

- All aluminum material, a simple and generous appearance.

- The print head is adjustable and very convenient.

- It is easy to install and remove.

- The dual guide rail design enables low noise and smooth operation of the machine.

Specifications of This Cylindrical Screen Printing Machine

| Package Dimensions | 22 x 10 x 7 inches |

| Item model number | SIC-28222 |

| ASIN | B07P17ZSGK |

| Max Printing Diameter | 11.8″ (30 cm) |

| Max Printing Girth | 15.7″ (40 cm) |

| Max Printing Area | 15.7″ x 17.7″ (40 x 45 cm) |

| Max Frame Size | 17.7″ x 19.7″ (45 x 50 cm) |

| Item Weight | 21 pounds |

| Manufacturer | Sign-in-China |

| Date First Available | February 21, 2019 |

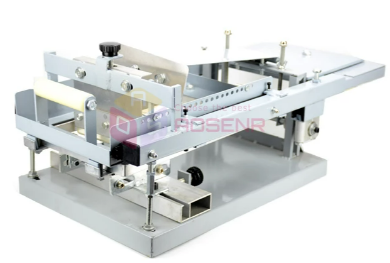

Top6: Manual Cylinder Screen Printing Machine

VEVOR is a world-renowned leading brand in the production of screen printing machines. VEVOR is committed to providing customers with robust and durable machines at extremely low prices. With excellent quality and fast and safe delivery, it has occupied the market in more than 200 countries.

The manual cylindrical silk screen printing machine with excellent quality also comes with many humanized details. It can be used to print cylindrical and conical objects such as cosmetic bottles, mugs, thermos, and more. The friendly non-slip handle design makes the whole printing process convenient and safe. The material of this screen printing machine is a durable steel plate, which makes the machine run more stably.

Reasons Why This Manual Cylindrical Screen Printing Machine Sells Well:

- Using durable steel plates, the sturdy structure ensures the stability of the equipment and long service life.

- 200*100mm large printing size.

- It can be adjusted to your desired height with an adjustable lift.

- The base is also adjustable for easy placement of prints.

Specifications of This Cylindrical Screen Printing Machine

| Model | TX-X1 |

| Screen frame size | 320 * 210mm |

| Maximum printing diameter | Φ80mm |

| Maximum printing circumference | 200mm |

| Maximum Printing area | 200 * 100mm |

| Gross Weight | 15kg(33.06lbs) |

| Package Size | 56 x 24 x 26 cm/22.05 x 9.4 x 10.23 inch |

Top7: Automatic Cylinder Screen Printing Machine

This is a cylindrical silk screen printing machine for bottles, lipstick, and cosmetic bottles. This multifunctional screen printing machine is suitable for all kinds of round, oval, conical flasks. Surprisingly, this screen printing cylinder press comes with oval, round, and flat worktables. This design can meet different shapes of printed objects.

The cast aluminum frame makes this machine lightweight and strong. And it is easy for the operator to adjust. You can use it to print large size objects. You also receive a toolbox and a manual instruction booklet when you receive the machine.

Reasons Why This Manual Cylindrical Screen Printing Machine Sells Well:

- With no printing without stopping the ink scraping function prevents the ink from drying out.

- Built-in 4-bit automatic counter.

- The microprocessor control makes the operation simple and the operation stable and accurate.

- The squeegee is automatically balanced during the printing process.

- Features an extra-long slider stroke for printing large size jobs.

Specifications of This Cylindrical Screen Printing Machine

| Control | Automatic |

| Number of colors | Color |

| Applications | For plastic bottles |

| Other characteristics | Flat bed, semi-automatic |

| Printing speed | 1,800 p/h |

| Frame | Cast aluminum |

Top8: SPS VITESSA XP STOP Cylinder Screen Printing Machine

With its sturdy construction and easy-to-operate features, this cylinder screen printing machine has clearly become one of the best-selling machines in the world. Operator comfort is also part of the innovation of this cylindrical printing press. SPS TechnoScreen has been in the screen printing field for over 60 years. In addition, SPS also provides technical support and installation services to customers. If you don’t know how to do it, SPS also offers training courses.

Reasons Why This Manual Cylindrical Screen Printing Machine is So Popular:

- After bold innovation, the operation is more humanized.

- Sturdy construction.

Technical Specifications of This Cylinder Screen Printing Machine

| Specification | Unit | XP57 primeline | XP71 classic |

| max. sheet size | mm | 550 * 750 ¹ | 750 * 1.060 |

| min. sheet size | mm | 250 * 300 | 280 * 420 |

| substrate thickness | mm | 0,07 – 0,8 | 0,07 – 0,9 |

| print frame, o/d | mm | 960 * 960 ¹ | 1.140 * 1.280 |

| print frame, o/d (opt.) | mm | 880 * 880 ² | 1.250 * 1.320 |

| max. cycle speed | iph | 4.500 | 4.000 |

| length (incl. feeder) | mm | 3.460 | 4.260 |

| width (excl. walkways) | mm | 1.830 | 2.165 |

| height | mm | 1.650 | 1.660 |

Top9: Manual Press Screen Cylinder Printing Machine

The manual screen printing machine is perfect for home use as well as for small businesses. This machine is small in size, but cost effective. It is simple and easy to operate, making it ideal for inexperienced operators.

It can be used to print any cylindrical products such as bottles, pens, cups, etc. The width of the machine’s table can be adjusted manually according to different diameters. The surface of the machine is smooth, not easy to scratch, and has a long service life, making it an ideal choice for you.

Reasons Why This Manual Cylindrical Screen Printing Machine is So Popular:

- The surface of the machine is smooth and comfortable to the touch.

- Manual cylindrical screen printing machine.

- Suitable for single color printing various cylindrical objects.

- Metal screen frame or wooden screen frame can be used.

- The screen frame can be adjusted up and down.

Specifications of This Cylinder Screen Printing Machine

| Type | Hand Tool Parts |

| Model Number | 0457X |

| Model Name | TX-X1 Manual Pen Silk Screen Printing Machine |

| Max Frame | 320*210mm |

| Max Diameter | φ60mm |

| Max Circumference | 200mm |

| Max Printing Size | 200*100mm |

| Dimensions (L*W*H) | 680*310*220mm |

| Weight | 20kg |

Top10: Cylindrical Screen Printing Machine with Optical Sensor

This is a medium-sized servo motor screen printing machine, you can use it to print any round objects. It is suitable for bottles, plastic tubes, cups and other objects. Printing with this cylindrical printing press is fast, good quality, and has low sound, almost no noise. It comes with a color register sensor, easy color register and high precision.

Reasons Why This Manual Cylindrical Screen Printing Machine Sells Well:

- German imported optical sensor.

- PLC control system, servo motor drive. Easy to make color registration more accurate.

- With blowing function, can print part of soft bottles.

- With color registration sensor, easy color registration and high precision.

- Alignment accuracy is 0.05mm.

Specifications of This Cylinder Screen Printing Machine

| Control System | PLC + HMI |

| Start Method | Panel | Pedal |

| Locating Device | Optical sensor |

| Squeegee Pressure Control | Regulating valve |

| Vertical Driven | Pneumatic |

| Transverse Driven | Servo motor |

| Jig Driven | Servo motor |

| Vertical Stroke | 100 mm |

| Transverse Stroke | 400 mm |

| Machine Speed | 600 – 800 cycles/hr |

| Max Print Size | 300*390 mm |

| Printable Diameter | 5 ~ 150 mm |

| Print Diameter (360 degree printing) | 115 mm |

| Max Length of Object | 300 mm |

| Power Supply | AC 110/220V, 50/60Mhz |

| Air Supply | 5 ~7 Bar |

Conclusion of the Top 10 Cylinder Screen Printing Machine:

The 10 best screen printing cylinder presses mentioned above are popular among customers worldwide. In summary, the most popular screen printing cylinder presses have the following characteristics in common.

First: Simple Operation

After receiving the machine, customers do not need special training to complete the installation and use of the cylindrical silk screen printing machine independently.

Second: High Cost Performance

The purchase cost and maintenance cost of the machine are within the customer’s reach. At the same time, the machine itself has a long service life.

Third: Practicality

That is, the screen printing machine can really meet the needs of the user, to achieve the user’s ideal screen printing effect.

Fourth: Perfect After-sales Service

Customers can enjoy a series of after-sales services from the manufacturer after they have purchased the machine.

As a professional and experienced manufacturer of cylindrical screen printing machines, ONCE has been favored by many customers at home and abroad. Whether you are interested in the above 10 best cylinder screen printing machines or other flat screen printing machines, bottle printing machines, please contact us and let us understand your needs so that we can provide you with professional purchase solutions.