Centrifuge tubes are critical lab tools. Scientists and medical professionals use them worldwide. These tubes should have clear, permanent graduations for measurements and branding. The screen-printing machines for centrifuge tubes made the results above possible. People know them for their speed, precision, and consistency. This guide will help manufacturers pick a screen printer for making centrifuge tubes. It simplifies the decision-making process. Key highlights, decision factors, and practical suggestions are all included.

You must assess yourself to select a good screen printing machine. The best machines use the right mechanics to make centrifuge tubes.

Key Factors to Consider When Choosing a Screen Printing Machine

1. Automation and High-Production Efficiency

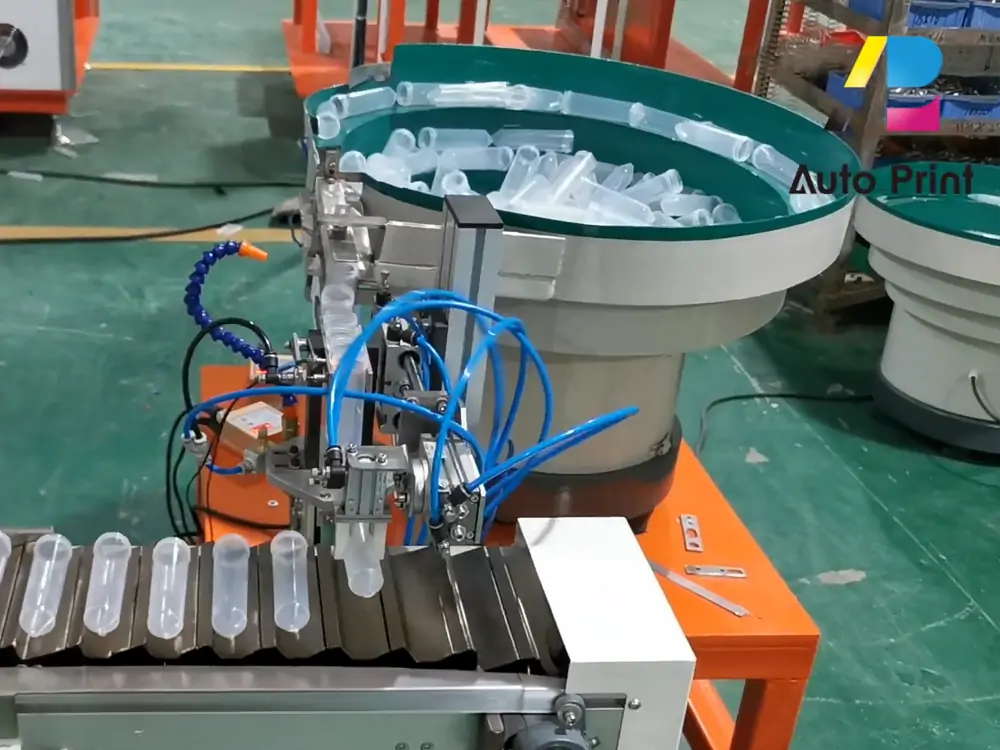

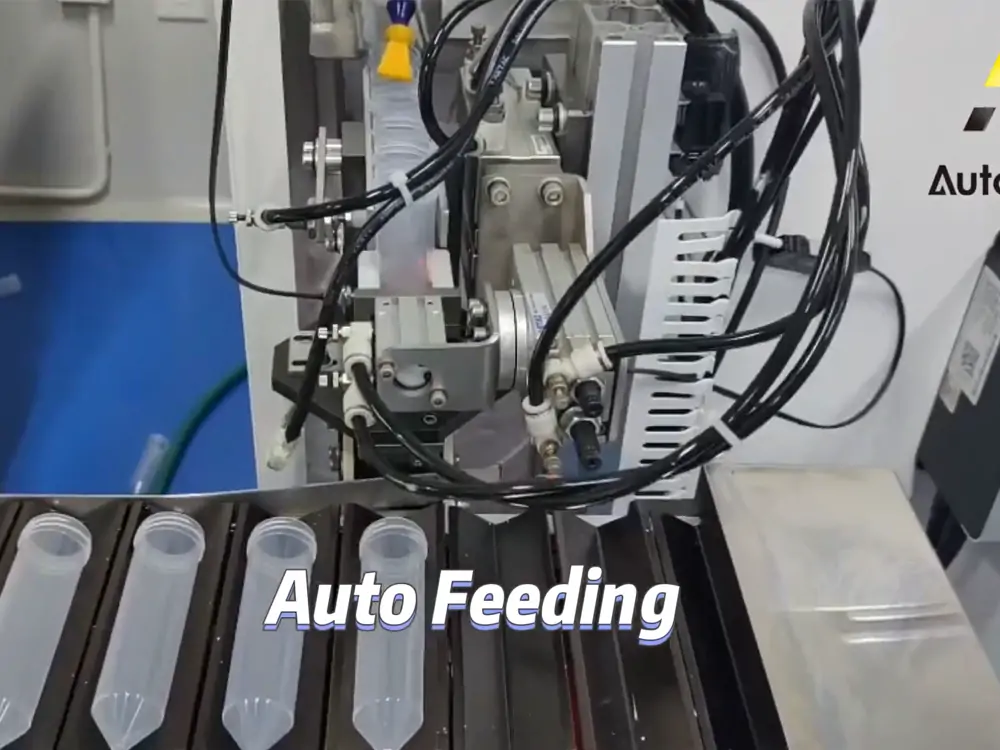

Contemporary production of centrifuge tubes requires a high-volume, low-profile production line. Manufacturers design automated screen printing machines to handle these demands with high efficiency.

- Streamlining Operations: The article shows that automation enables fast, low-error, low-waste operations. Continuous feeding machines are more efficient. They require less human input.

- Multi-Color Capabilities: We can print several colors in one cycle, ensuring the correctness of our logo, scales, and ID features.

- Examples in Practice: Consider an assembly line that makes thousands of 50ml centrifuge tubes daily. We could not manage this traffic without an automated system, and even with one, it would be inconsistent and inefficient.

2. Versatility in Design

Centrifuge tube racks come in various widths and depths. They can hold 15 ml to 50 ml tubes. The machine should cater to this diversity:

- Adaptability: The material’s dimensions must be variable. However, nothing can affect print sharpness.

- Customizable Printing Options: Machines must allow for versatile, multipurpose printing. They should print anything from a simple logo to complex scales, like those on our products. For businesses with various product forms, the vehicle must be flexible.

3. Dimensions and Eco-Friendly Colors

Centrifuge tube markings in labs must resist chemicals, autoclaving, and harsh conditions.

- Chemical-Resistant Inks: They withstand rigorous lab wiping and resist fading.

- Eco-Friendly Printing: New trends show a growing awareness of inks’ environmental effects. Manufacturers are opting for eco-friendly inks. Such inks help ensure that the machines in these businesses follow environmental laws.

Here are key points to consider when choosing a screen printer for centrifuge tubes. So, choosing the best machine depends on the manufacturers’ goals, materials, and needs.

4. Precision and Detail

The lab used the centrifuge tubes. They need accurate marking to hold their structure. Key factors to consider include:

- Fine-Scale Alignment: Instruments should have better tech for placing scales and bar codes. Also, they should improve logo placement. Poor alignment of these markings can actually create problems with the use of the tube.

- High-Resolution Output: Both text and symbols must be transparent, even with small motifs.

A pharmaceutical lab’s biological centrifuge tube must-have volume indicators and clear text.

5. Material Compatibility

Most centrifuge tubes are PP or PE, non-porous materials. They come in ‘flat’ bottomed, autoclavable versions. Most lab suppliers now offer ‘low-bind’ tubes. Printing on these surfaces requires specialized technology:

- UV-Curable Inks: These inks guarantee good adhesion and durability with PP and PE.

- Optimized Machines: For instance, Once-Tech’s centrifuge tube printers are for non-porous surfaces.

6. Automation Level

Your production scale defines how much automation is possible and necessary.

- Fully Automated Machines: They are best for large production companies. They continually feed the machines, have better positioning, and print quickly.

- Semi-Automatic Machines: These models suit small productions or niche industries. They are fairly priced, with many great features.

7. Maintenance and Support

Screen printing machines are highly developed pieces of equipment in this production line. Ensuring reliable maintenance and support is crucial for sustained productivity:

- Low-Maintenance Designs: Mature machines with modular parts and user-friendly systems need little repair. They cost less.

- Supplier Support: Choose venous. It has tech support, a guarantee, and an after-sales service to protect your investment.

8. Cost-Effectiveness

Striking the right balance between cost and performance is essential for manufacturers:

- Initial Investment: Expensive machines may be costly at first. However, they have low operating costs and produce a higher-quality end product.

- Long-Term Efficiency: Energy-saving, durable, eco-friendly products give the best returns.

- Product Recommendations: Sometimes Tech Centrifuge Tube Printing Machines. One-Tech is a one-stop solution provider. We supply screen printing machines. They are designed for making centrifuge tubes. These machines have various features. They are also very reliable and good for manufacturers.

Common Mistakes and How to Avoid Them

1. Ignoring Material Compatibility

Mistake: A failure to consider the compatibility of materials. Lack of proper use of a machine intended for PP/PE surfaces leads to low-quality ink and fadeaway prints.

Solution: Recycle using machines that can handle these materials. Once-Tech machines support UV-curable inks and high adhesion.

2. Failure to Consider Production Scale

Mistake: It’s a mistake to choose a machine with few features. It’s also wrong to pick an overly complicated one.

Solution: Find your production proportions. Then, choose suitable machines, either fully or semi-automatic.

3. Failure to Follow Up After the Sale

Mistake: It is important to know that even the most developed equipment needs help. If there is no sound support, they are part of the problem. It causes longer downtime when selecting a supplier.

Solution: Source from suppliers who can also provide after-sale service. This includes training on the equipment and product. It covers troubleshooting and spare parts for repairs or service.

Why Choose Once-Tech Screen Printing Machines?

- Automation Excellence: All feeding and printing processes are automated. This ensures high productivity and reliable results.

- High-Resolution Printing: Best for fine details, scale info, and scripts. It produces very sharp images. These machines are for lab-grade PP and PE. They provide high ink adhesion and durability.

- Material Compatibility: Specifically designed for PP and PE surfaces, ensuring superior results for lab-grade products.

Who Can Benefit?

Laboratory Consumables Manufacturers: Ideal for high-volume production lines where speed, precision, and durability are critical.

Small to Medium Customization Businesses: Perfect for niche or small-scale production with straightforward operation and customization options.

Some Other Considerations for the Implementation of the Concept

When buying a screen printing machine, consider future needs and trends.

- Integration with Smart Technologies: The latest products have digital controls and smart features. They can be easily integrated.

- Sustainability Goals: They help the organization meet official requirements. They require using environmentally friendly practices, such as low-impact printing machines.

- Scalability: Choose machines that can boost throughput as your business grows. This will give you the best value for your money.

Conclusion

The best screen printing machine for plastic centrifuge tubes must meet certain criteria. It must be precise, compatible with the material, automated, and affordable. Once-Tech centrifuge tube printers have key benefits. They are high-res, durable, and flexible. They meet manufacturers’ production line demands. The video says that using the right tools improves performance. It also builds a strong foundation for growth in a competitive global market. You can view Once-Tech’s entire line of centrifuge tube printing machines on Once-Tech.