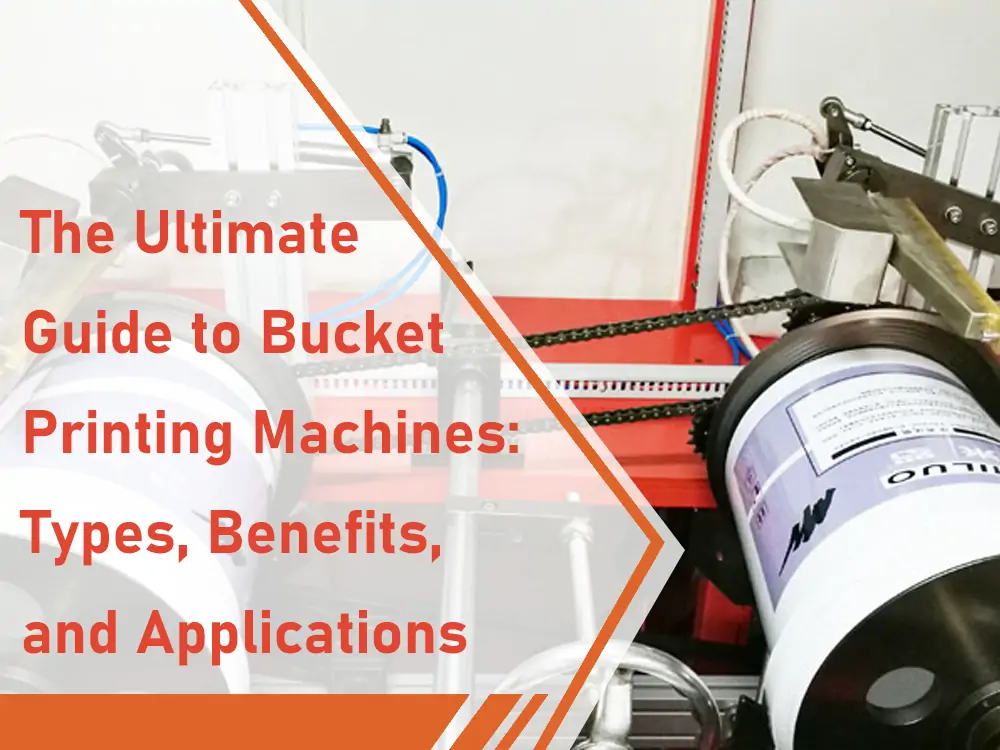

Bucket printing machines are designed to print patterns, logos, or messages on plastic, metal, or glass buckets. These machines have become indispensable in industries such as food packaging, paint, and chemicals due to their ability to create complex, durable, and customizable designs. Beyond their functionality for storage and transport, printed buckets serve as a marketing tool, help meet legal requirements, and reinforce branding. They ensure accuracy and uniformity, which are critical for maintaining a consistent brand image across products. Whether it’s a single-colored logo or intricate multi-colored graphics, these prints play a crucial role in product recognition in the market.

With advancements in automation and printing technologies, bucket printing has evolved significantly. Earlier manual methods have been replaced by fully automatic systems that meet the demands of high-volume production while maintaining quality. Automation ensures consistency, reduces errors, and enables machines to operate 24/7 to meet tight deadlines. For companies, these systems help cut costs, minimize reliance on labor, and ensure high-quality outputs, making them a wise investment in today’s competitive market.

Some of the bucket-printing machines are as follows:

Bucket Screen Printing Machine

What is screen printing?

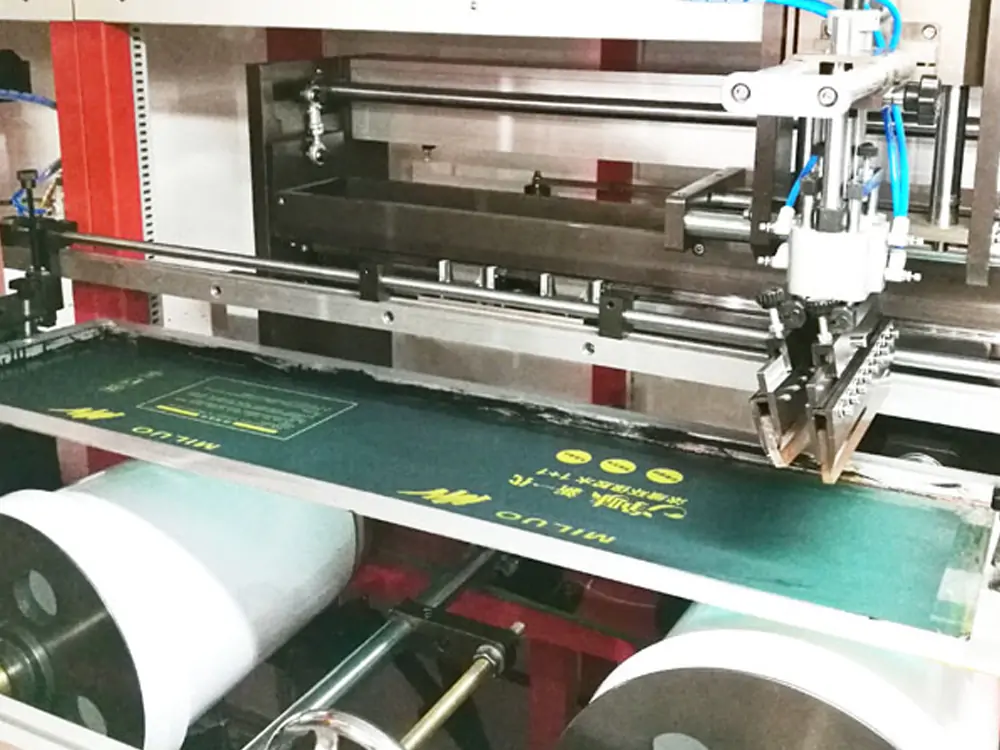

Screen printing, or serigraphy, is an old printing method. The process pushes ink through a screen or stencil onto the surface. It is instrumental in creating prints that are highly archival and shiny. The process involves making a stencil (or screen) for each color in the design. Then, we drive the ink through the screen onto the bucket’s surface.

The type of mesh, polyester or nylon, and stencil accuracy define print sharpness. Screen printing is ideal for designs with bold colors and simple shapes.

Uses of Bucket Screen Printing Machines

Used to make printed plastic and metal buckets for paint, chemicals, and construction.

It is very effective for creating multicolor prints or logos since the ink is very resistant.

Advantages

Cost-effective: Large-scale manufacturing will make much sense once the screens are prepared.

Durability:

The print must not fade, scratch, or deteriorate in harsh conditions. It must have a long-lasting finish.

Heat Transfer Printing Machines for Buckets

Heat Transfer Printing Overview

Heat transfer printing uses a design printed on a thin film or paper. It applies heat and pressure to transfer the design to the bucket’s surface. It can produce detailed prints with few features. So, it suits designs with many details.

Applications

Common in industries that require precise, high-definition graphics. This includes consumer product branding. The provided formulations are effective on both the plastic and metal surfaces.

Advantages

- Higher resolution: Offer better print resolution and hue quality than conventional prepress methods.

- Versatility: It works with all bucket shapes and curved surfaces. Other Bucket Printing Technologies are online, network, feeder, recirculation, snap-through, scissor, cutter, flying, non-contact, dynamic, mechanical, hybrid, tape, dispensing, contact, impact, pen, and fluid.

Other Advanced Bucket Printing Technologies

- Pad Printing Machines: Ideal for printing on curves and rough surfaces. They likely suit bucket-shaped products.

- Flexographic Printing Machines: They are famous for high-volume, multicolor jobs, especially in packaging.

- Direct-to-Object (DTO) printers: A new technology that cuts through the substrate. It allows for much faster, more versatile printing.

Significant Advantage of Bucket Printing Machines

Automated bucket printing machines aim to work faster than manual methods. They seek to reduce time by improving work quality. It also helps you work 24/7 to finish more quickly, with slight manual input. More connectivity to assembly lines boosts productivity. It makes the app essential for high-volume production.

Improved print quality

Today’s bucket printers use new tech for high-res prints. The product’s value and appeal grew in competitive markets. This was due to its consistent color and brightness. This enhanced print quality directly relates to better brand identification and customer trust.

Cost-Effectiveness

The company could cut outsourcing costs by investing in bucket printing machines. Centralized printing can help organizations. It can save on third-party costs and improve control over the print timetable. They also help reduce waste material usage and reduce employment expenses, making it a worthy investment in the long run.

Targets of Customization and Branding

Bucket printing machines let owners easily swap designs. This suits different markets or seasons. These machines let brands print custom packaging for logos, labels, and graphics. Customization helps to raise brand awareness. It also boosts customer loyalty.

Uses of Bucket Printing Machines

Specialized Uses

Paint and Chemical Industry:

Buckets for storing paints, oils, or chemicals must be labeled for safety.

Food and Beverage Industry:

Printed buckets are for food packaging and labeling. They also improve the buckets’ shelf appeal.

Cosmetic and Personal Care Industry:

Custom-printed buckets enable brands to give their products attractive packaging, making them unique.

Industrial and Household Products:

Highly durable printed buckets are in high demand in construction, gardening, and cleaning.

Materials and Surfaces

- Plastic Buckets:

Screen and heat transfer printing are acceptable for used plastic buckets. They are typically made from HDPE or PP. - Metal Buckets:

Screens and stencils need extra skills for printing on galvanized steel, aluminum, and other tough metals. - Glass and Ceramic Containers:

Although not as widespread as the previous types, such materials demand the use of complex patterns in printing. Of all the printing machines in the buckets, how does one select the best bucket printing machine?

Factors to Consider

- Material Type: Check if the machine can print on your bucket’s material, such as plastic or metal.

- Volume Requirements: A high-speed machine is needed for high-volume work or a small solution for unique products.

- Budget: Compare the installation and long-term costs of the equipment to find the best solution.

Comparing Technologies

Screen Printing vs. Heat Transfer Printing:

Screen printing is best for single-color prints on many products. Heat transfer printing is ideal for detailed designs with many colors.

Choosing Based on Application Needs:

Decide based on the product’s surface, the design’s complexity, and the ability to make it.

Conclusion

Summary of Key Points

Incredible packaging firms need bucket printing machines. They want high-quality, custom packaging. They help companies by turning investments into profits. Their low cost, high productivity, and usefulness drive this.

Why Need a Bucket Printing Machine?

The correct bucket printing machine is cost-effective and adaptable. It supports company branding, giving good value for the money spent.

Final Thoughts

Choose bucket printing tech that meets your needs and helps your business grow.

Hurry up and call Once-Tech today. Hire our pros. Meet our machines. Our prices are low and based on your needs.