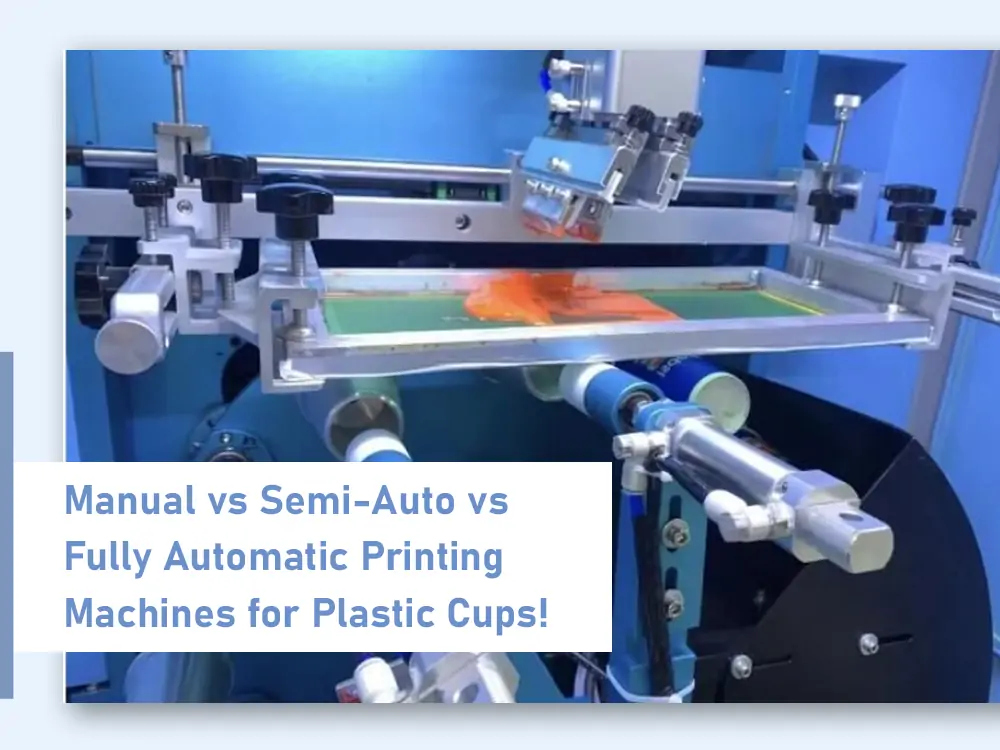

You must have seen colorful plastic cups with beautiful designs. Have you ever wondered how those designs are printed so perfectly? The answer lies in the plastic cup printing machine. Interestingly, this machine is not just one kind; it comes in three types. That’s where a debate begins: manual vs semi-auto vs fully automatic printing machines for plastic cups.

Each of these machines works differently and offers unique features. Also, their suitability varies with business size and needs. That’s why knowing their key difference is crucial to choosing the right machine for your business. Feeling confused about which machine to go for? Worry not! This guide will make everything easy for you by comparing all three types. Let’s get started!

Overview of Manual, Semi-Auto, and Fully Automatic Cup Printing Machines

Before proceeding to the types, let’s first understand what a cup printing machine is!

A cup printing machine is a special device that prints colorful designs directly onto the cup surface. This machine prints designs like logos and images using special techniques. Those include UV printing, screen printing, or pad printing. This eliminates the need for stickers and makes the cup look more attractive.

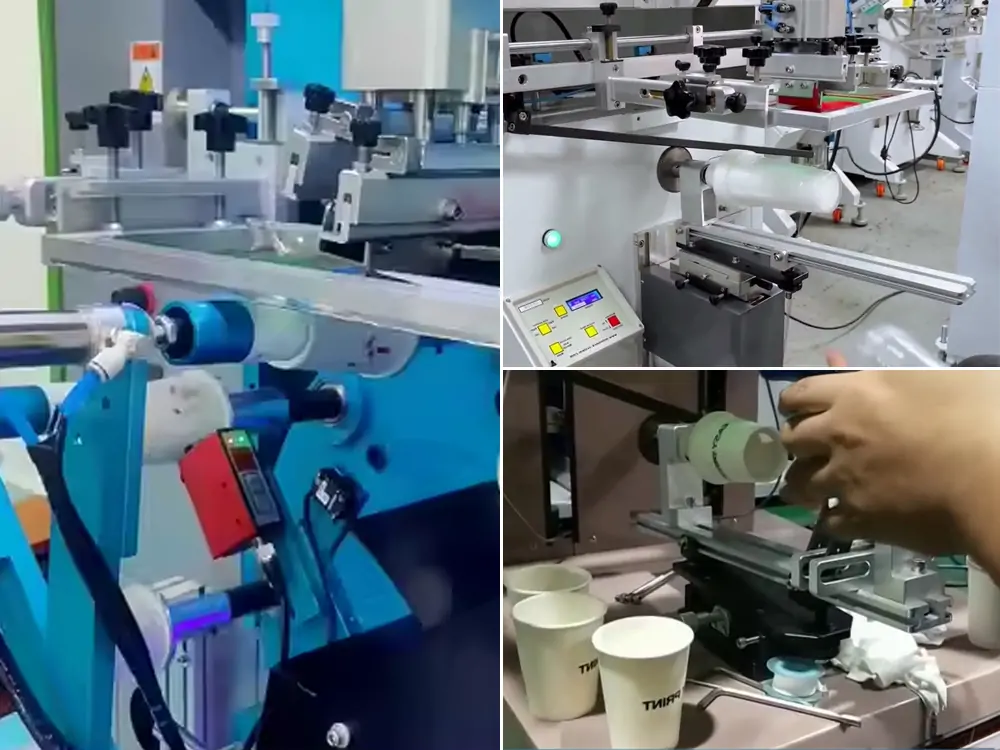

As I mentioned, プラスチックカップ印刷機 come in three types. The first one is a manual printing machine. This is a straightforward type that works with human interaction. A person handles all steps of the printing process. For example, an operator places the cup, aligns the print, applies the ink, and removes it. No part of these machines works automatically.

The second type is a semi-auto printing machine. It is a mix of manual and fully automatic technology. So, some tasks are done by machines, while others still require human input. For example, machines automatically print the design and handle the ink. However, the human contribution is needed to load and unload the cups.

The third one is a fully automatic printing machine. As the name suggests, this high-end machine does all the tasks. There is no human interaction, which makes it more accurate and efficient. For example, a stack of empty cups is loaded into the machine. After that, it picks the cup, aligns it, prints and dries it, and removes it.

Manual vs Semi-Auto vs Fully Automatic Printing Machine for Plastic Cups: Key Differences

I hope the overview gave you a basic understanding of all three types of cup printing machines. Remember, each machine has its pros and cons. So, to understand them completely, let’s compare them head to head to decide which suits your project!

1- Level of Automation & Speed of Operation

The level of automation means how a machine works itself without human need. The manual cup printing machine has the lowest automation level. Everything is done by hand. You have to place the cup, start printing, and remove the cup after printing. All this reduces the speed of the overall printing operation.

However, semi-auto cup printing machines have a medium level of automation. This machine can do some of the tasks by itself. For example, it prints the design and dries the ink automatically. However, you must still be involved in this process for some tasks. Due to this, printing processes become fast to some extent but still take time.

Lastly, it comes to fully automated printing machines. These machines have the highest level of automation. All tasks from loading to printing and removing cups are done by machine. So, such machines can print many cups in less time. As a result, the printing operation becomes very fast and efficient.

2- Labor Requirement & Maintenance Needs

Maintaining cup printing machines is a fundamental and vital difference to understand. For example, manual cup printing machines are straightforward and involve simple parts. They do not include complex electronics or sensors, making maintenance effortless. However, regarding labor requirements, manual machines are demanding.

Each step of printing must be done by hand. So, these machines require a large amount of labor. Conversely, semi-auto machines reduce physical workload by automating some steps. For example, these machines apply the ink and rotate the cups. As a result, labor needs are moderate. Regarding maintenance, semi-auto machines are slightly complex.

They involve motors, switches, and control panels that require proper maintenance. In contrast, fully automatic printing machines run with minimal human involvement. Almost all the tasks, feeding, printing, and removing the cups, are automatic. Operators are usually needed only for monitoring and quality control.

That’s why these machines require little to no labor. However, automatic machines are demanding in terms of maintenance. They involve advanced machinery features and electronic systems. Those parts require regular servicing, like lubrication, calibration, and software updates. All this needs professional maintenance to ensure quality.

3- Print Quality & Consistency

Print quality refers to how sharp and vibrant the printed design appears on the cup. Consistency indicates whether results stay the same across thousands of prints. Let’s first begin with manual cup printing machines. As I said above, these machines work with human involvement. So, the print quality depends heavily on the operator’s skill.

That’s why printing errors like smudges and uneven color are most likely to appear. Moreover, consistency is also harder to maintain, especially in long production runs. On the other hand, semi-auto machines perform better in this area. Automated components control some parts of the printing process. So there is better alignment and ink control.

This leads to more uniform printing compared to manual machines. However, as you can see, this machine still involves some manual steps. Therefore, slight variations in design can still occur due to misalignment. Now, if we look at fully automatic printing machines, they are highly efficient in this term. These machines have the highest automation level.

There is no chance of human error, which enhances the quality. This machine ensures every cup is printed with the same speed, pressure, and alignment. So, even a thousandth cup looks exactly like the first cup in terms of quality and print. With automatic machines, you can get high-quality and professional-level prints on a large scale.

4- Production Volume Capability

Production volume shows how many cups a machine can print at a particular time. All three of these machines behave differently in this regard. Let me first clarify the manual cup printing machine. As you know, these machines rely on human efforts, so the overall process is slow. This makes them ideal for small custom orders.

On the flip side, semi-auto machines are fast. Some parts are automated and don’t need human involvement. Operators only need to manage a few tasks, like loading and unloading. This improves the production capacity to some extent. Hence, these machines are designed to produce medium-volume printed cups.

In contrast, fully automatic printing machines are entirely automated. These machines work continuously and handle all tasks without human intervention. As a result, they can print a large number of cups in no time. Such high speed makes them ideal to meet the needs of high production volume. They are perfect for companies with heavy daily orders.

5- Ease of Use & Training

Another difference between these three cup printing machines is how easy they are to use. Let’s first discuss the manual cup printing machine. This machine is generally the simplest to understand and operate. It has fewer buttons, no digital control, and straightforward mechanical steps. So, anyone with basic instructions can learn how to use it.

However, if you want to achieve high-quality results, you should have more practice. For example, aligning the cup correctly and applying the amount of pressure requires experience. On the other hand, semi-auto printing machines are slightly more complex. They include some automated functions like motor-driven movements.

So, you have to learn how to operate the control panel and adjust settings to avoid errors. While it’s not very difficult to operate, little training and hands-on practice are crucial. Once you learn the basics, it will be far easier to manage later. Now, if we discuss fully automatic printing machines, they are very complex.

These machines involve digital control, sensors, and programmable settings. So, these systems require more technical knowledge to understand them. You need practice and training to operate functions like multi-color printing and touchscreens. However, once you are trained, the machines become efficient and easy to work with.

6- Space & Setup Requirements

Space and setup requirements also differ for each type of cup printing machine. For example, manual machines are the most compact of all. They usually have small frames and don’t require additional equipment. Moreover, their setup is also simple, involving just a power source. It means you can easily adjust them in small places.

On the flip side, semi-auto machines are larger and include more components. For example, these machines involve control panels, automated parts, and motors. Moreover, some of their functions also require manual involvement. So they also need a dedicated room for operators to work and move freely. However, these machine setups are still manageable in medium-sized factories.

Fully automatic printing machines are the largest and most complex. These machines include feeders, dryers, conveyors, and control systems. Because of their big size and automation, they require plenty of floor space. Moreover, their setup involves professional installation and system calibrations. So these machines are ideal for large manufacturing facilities.

7- Suitability for Business Types

Each type of printing machine is best suited for different kinds of businesses. For instance, manual printing machines are ideal for small businesses and startups. A manual machine is perfect if you are just starting out producing cups in small batches. HOW? It does not require a big space or a large staff. Moreover, it is also great for operations that require flexibility.

On the other hand, semi-auto machines are perfect for growing businesses. They suit businesses that need to increase output without jumping into industrial setups. These machines strike a perfect balance between manual and automation control. This makes them ideal for medium-sized companies with moderate to high demands.

In contrast, fully automatic machines are suitable for large-scale cup printing businesses. These machines are high-speed and efficient. As a result, they can print thousands of cups in less time. This helps you meet tight deadlines and large numbers of orders. So overall, automatic printing machines suit large-volume manufacturing companies.

8- Cost and Affordability

Cost is one of the significant factors that differentiate cup printing machines. Each type of machine has a different price range. For example, manual printing machines are a cost-effective option with low running expenses. WHY? First, they involve simple parts that come at lower prices. Moreover, these machines don’t require skilled staff.

This eliminates the need for labor. Lastly, manual machines also require less maintenance. They don’t wear out quickly and last long, reducing their cost. On the flip side, semi-auto machines are moderately priced. They are more expensive than manual machines due to partially automated features. This also increases the cost of maintenance and labor to some extent.

Finally, fully automatic printing machines are more expensive than all others. The first reason is their advanced technology and automatic systems. To operate those systems, you must hire skilled staff and proper training. Also, these machines require regular maintenance, which further enhances the cost. However, in the long run, these machines are very cost-effective due to their high production speed.

Which Printing Machine Should You Choose, Manual, Semi-Auto, or Fully Automatic?

この質問に一言で答えることはできない。プロジェクトのニーズによって大きく異なります。ですから

Manual printing is the best choice if you’re new to the cup printing business. Semi-auto machines are ideal if your business is growing and you need cost-effective yet fast production. But if your business requires mass production with high speed and accuracy, I recommend fully automated machines.

しかし、万能のマシンは存在しないことを覚えておいてほしい。それぞれに長所と短所がある。ですから、最終的な選択のためには、あなたのビジネスの性質を理解する必要があります。例えば、手動のカップ印刷機はシンプルで操作が簡単です。熟練工を雇うことなく稼働させることができます。しかし、これらの機械は肉体的な労力を必要とするため、大口の注文には不向きです。

しかし、半自動印刷機は手動印刷機よりも優れている。スピードが速く、手作業が少なくて済む。さらに、このような機械は価格も安く、メンテナンスも比較的簡単です。そのため、これらの機械は、以前よりも多くのカップを必要とする中規模企業には最適である。しかし、いくつかのステップでは、これらの半自動機はまだ人間の関与を必要とする。

全自動マシンは大規模生産用に設計されています。すべてのパーツが自動的に作動し、人の手を必要としないため、非常にスピーディーで正確です。これらの機械は、数千個のカップをあっという間に作ることができる。しかし、これらの機械は、最初は高価ですが、長期的にはコストに優しいことができます。

よくある質問

初心者に最適なマシンは?

手動のカップ印刷機は初心者に最適です。複雑な機械部品を必要としません。そのため、基本的な手順で効率的に操作することができます。

これらのマシンのスペアパーツはすぐに入手可能か?

そう、これらのマシンのスペアパーツは入手可能だ。これは大きなメリットだ。部品が消耗した場合、信頼のおける 印刷機メーカー.

カップ印刷に使われるインクの種類は?

カップ印刷のインクの種類は、印刷方法によって異なる。標準的な印刷インキには

- UVインク

- 食品用インク

- 溶剤系インク

結論

カスタムメイドのカップは、この競争社会におけるブランディングとマーケティングのために普及している。しかし、優れたデザインのプラスチックカップの裏には、適切な機械がある。これらの機械には、主に3つのタイプがある。カップ印刷ビジネスの初心者であれば、その基本や違いを理解することは非常に重要です。この記事では、各機械の種類についてのすべてを探りました。

例えば、手動の印刷機はシンプルで操作が簡単だ。小規模ビジネスには最適だ。しかし、セミオートマシン(半自動印刷機)は、その簡易版である。これらの機械の一部は自動化されているが、一部は人間の操作が必要である。最後に、全自動印刷機は高度で効率的です。高速かつ正確で、大規模な生産に最適です。